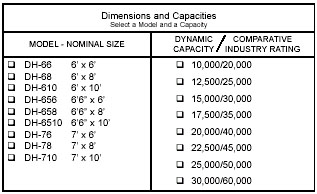

DH

Series Hydraulic Dock Leveler

|

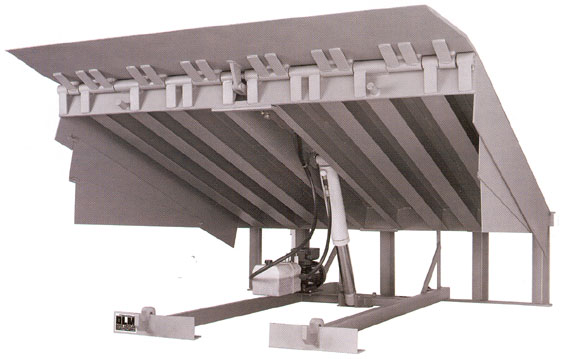

The

"DH" Series hydraulic leveler is value engineered to meet both

application and budget constraints while

maimizing productivity, optimizing efficiency adn improving safety. From

superior structural design to unlimited

operator features, the "DH" Series hydraulic leveler is a wise

investment. |

|

|

|

|

|

|

|

| Standard

Features Include |

|

|

|

• Simple Push Button

Control

• Four Sided Box Construction - Deck Assembly

• Inverted Single Acting Hoist Cylinder

• Full Hydraulic Lip Activation

• Velocity Safety Stop

• Lockout/Tagout Maintenance Strut |

|

• Night Locks/Cross Traffic

Support

• Motor Overload Protection

• Low Maintenance Design

• Full Range Toe Guards

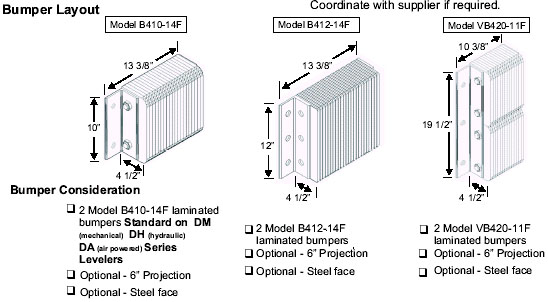

• Two (2) B410-14 Laminated Bumpers |

|

|

|

|

|

Heavy

Duty Single Action Main Cylinder |

|

|

•

Inverted cylinder mount keeps

hose routing protected under

deck.

• Chrome plated 3 1/2" rod with

3" ID bore adds stability during

ramp hoist and "Lock-Up" con-

ditions.

• Extenally mounted non-adjustable,

velocity safety fuse prevents free

fall of loaded platform to 3". |

|

|

|

|

|

|

|

|

| Structurally

Superior |

|

|

|

|

•

Over 29" of direct rear hinge support - heaviest in the

industry.

• Four sided box construction provides unmatched

structural integrity.

• Deck construction is capacity dependent to insure your

loading bridge matches the demands of the approved

work load.

• Leveler lip and deck are constructed with high-strength

55,000 lb. yield, safety treadplate.

• Deck support members are application dependent |

|

|

|

|

|

|

|

|

|

|

|

|

|

Positive

Lip Extension |

|

|

•

Nickel plated lip cylinder for added corrosion

protection.

• Fully yield design to protect mechanism from

backing truck.

• Cushioned lip fall. |

|

|

|

|

|

|

|

|

Low

Capacity - Roll form "C" channel

Medium Capacity - Structural "C" channel

Heavy Capacity - Structural "C" channel and "I" beam |

|

|

|

|

|

|

|

|

|

|

Clean

Sweep™ Frame |

|

|

|

•

Provides clear access to area

beneath platform.

• Allows easy removal of debris.

• Ideal where maintaining sanitary

standards is important. |

|

|

•

Close and consistent spacing of beams provide neces-

sary support for 3-wheeled and 4-wheeled fork

trucks. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Simple

Push Button Control |

|

|

|

|

|

|

|

|

|

|

•

Non-metallic Nema 4 single push button control.

• Control components are UL listed or recognized.

• Overload protection for motor is standard.

• Optional interlocking and integrated panels are

available. |

|

|

|

|

|

|

|

Lockout/Tagout

Maintenance Struts |

|

|

•

Permanently mounted, hinged

maintenance strut supports deck

during maintenance or inspection.

• Hinged maintenance strut lockout/

tagout capable. |

|

|

|

|

|

|

|

|

| Efficient

Power Souce |

|

|

|

|

|

|

|

|

|

|

•

1.5 HP totally enclosed fan cooled

(TEFC) motor.

• 115v single phase motor (3 phase

optional).

• Translucent tank, fast fluid level

inspection.

• Elevated frame mounted design

keeps clear of debris.

• Integral cartridge valve is built into

pump.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~ Add

items to your online shopping cart ~

Click the Price of the item you wish to

purchase. |

|

|

PRICES

FOR DH SERIES HYDRAULIC DOCK LEVELER |

| Size

Model No. |

25,000

CAP. |

30,000

CAP. |

35,000

CAP. |

40,000

CAP. |

45,000

CAP. |

50,000

CAP. |

60,000

CAP. |

| 6' x 6' |

|

|

|

|

|

|

|

| DH-66 |

1675# |

1695# |

1775# |

1795# |

1895# |

1915# |

2505# |

| 6' x 8' |

|

|

|

|

|

|

|

| DH-68 |

1985# |

1985# |

2065# |

2085# |

2185# |

2205# |

2795# |

| 6' x 10' |

|

|

|

|

|

|

|

| DH-610 |

2285# |

2285# |

2365# |

2385# |

2485# |

2505# |

3095# |

| 6.5' x 6' |

|

|

|

|

|

|

|

| DH-656 |

1875# |

1875# |

1955# |

1975# |

2075# |

2095# |

2685# |

| 6.5' x 8' |

|

|

|

|

|

|

|

| DH-658 |

2200# |

2200# |

2280# |

2300# |

2400# |

2420# |

3000# |

| 6.5' x 10' |

|

|

|

|

|

|

|

| DH-6510 |

2450# |

2450# |

2530# |

2550# |

2650# |

2670# |

3260# |

| 7' x 6' |

|

|

|

|

|

|

|

| DH-76 |

1915# |

1915# |

1995# |

2015# |

2115# |

2135# |

2725# |

| 7' x 8' |

|

|

|

|

|

|

|

| DH-78 |

2225# |

2225# |

2305# |

2325# |

2425# |

2445# |

3035# |

| 7' x 10' |

|

|

|

|

|

|

|

| DH-710 |

2540# |

2540# |

2620# |

2640# |

2740# |

2760# |

3350# |

|

Note: 60k CIR levelers hip standard with 18" lip and 6" bumpers.

If wall mounted retraints are to be added a

minimum of

2" cantilever bracket is required. 24" Pit standard on all 60k

and 10' levelers.

For special service range on 10' and 12' levelers consult us. |

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~ Add

items to your online shopping cart ~

Click the Price of the item you wish to

purchase. |

|

|

COMMON

"DH" OPTIONS |

|

|

|

| Description |

Prices |

| Nema 12 Controls - N12CB (Interlock Terminals) |

|

| 3 Phase Motor (208 & 480 Volts) |

|

| 3 Phase Motor (575 Volt) |

|

| Auto Return To Dock/Leveler Stored* |

|

| Quick Cycle Lip Extend Button (Must Select Nema 12 Control Box) |

|

| Quck Cycle Lip Extend/Leveler Stop Button (Must Select Nema 12 Control

Box) |

|

| Mushroom Style Emergency Stop Button |

|

| Additional Interlock Terminals (Must Select Nema 12 Control Box) |

|

| Grease Fittings |

|

| 3-Wheel Lift Truck Strapping |

|

| CleanSweep Frame |

|

| Rubber

Weatherseal (Foam Rear) |

|

| Brush

Weatherseal (Foam Rear) |

|

| Brush

Weatherseal (Brush Rear) |

|

| 18"

Lip |

|

| 20"

Lip |

|

| 24" Pit Conversion (Factory Installed) |

|

|

|

| *Must

Select Nema 12 control box. |

|

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~ Add

items to your online shopping cart ~

Click the Price of the item you wish to

purchase. |

|

|

OPTIONS |

Description |

Prices |

Yellow

Toe Guards |

|

Yellow

& Black Toe Guard Safety Type |

|

Grease

Fittings |

|

Smooth

Deck & Lip |

|

Abrasive

Finish on Deck & Lip (Includes Smooth Deck & Lip) |

|

Abrasive

Finish on Deck & Lip (On 4 Way Checker Plate) |

|

Full

Range Toeguards |

|

Extended

Lip Chamfer |

|

Reduced

Lip Crown (Range +6" - 8") |

|

3-Wheel

Fork Truck Strapping |

|

Auto

Return to Dock (must select Nema 12 Control Box) |

|

Quick

Cycle Lip Extend Button (must select Nema 12 Control Box) |

|

Quick

Cycle Lip Extend Button/Level Stop Button (must select Nema 12 Control

Box) |

|

Mushroom

Style Emergency Stop Button (Must Select Nema 12 Control Box on

DH Series) |

|

CleanSweep

Frame |

|

| Rubber

Weatherseal (Rear Foam) |

|

| Brush

Weatherseal (Rear Foam) |

|

| Brush

Weatherseal (Rear Brush) |

|

| 24"

Pit Conversion (blocked and elevated frame) |

|

| 18"

Lip |

|

| 20"

Lip |

|

| 22"

Lip |

Consult

us |

| Foam

Insulated Deck |

|

| Stainless

Steel Hinge Pins (Front and rear) |

|

Remote

Power Pack (Includes 25' Hose & Mounting Plate) |

|

Special

Pain Requirements |

Consult

us |

Spray

Metalized (Deck, Lip & Frame) |

|

Spray

Metalized (Deck, Lip & Frame Hydraulic Cylinder Casing) |

|

Hot

Dip Galvanized (Deck, Lip & Frame. Note: Minor Deflection May

Occur Druing

Galvanizing Process. Hydraulic Only Min. 45k Board) |

Consult

us |

Gray

Touch-up Spray Paint |

|

Yellow

Touch-up Spray Paint |

|

|

|

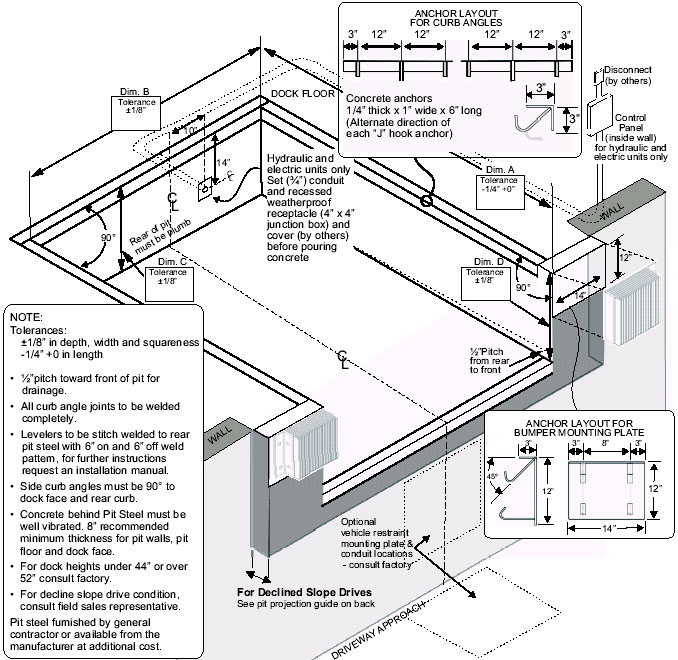

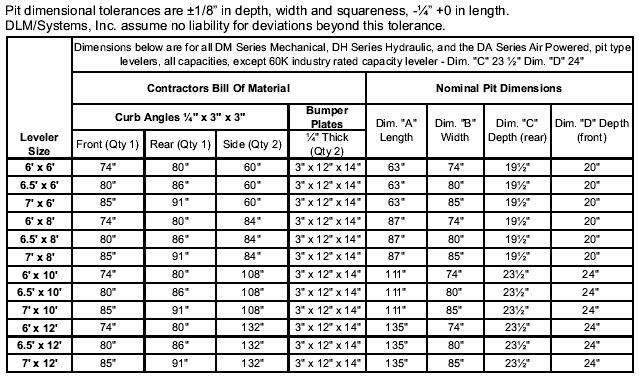

PIT

DETAIL FOR DH SERIES |

|

|

|

|

|

|

|

|

|

Pit

dimensional tolerances are ±1/8” in depth, width and squareness,

-¼” +0 in length.

We assume no liability for deviations beyond this tolerance. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Optional

Bumper Plates - in lieu of above |

|

|

|

|

|

11”

wide x 20” high (Qty 2)

11” wide x 24” high (Qty 2)

Other Bumper Embed ___________________ (Qty 2) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

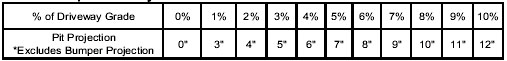

| Pit

Projection Guide for Decline Slope Driveways |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Rise

of

Driveway |

|

|

|

|

|

|

|

|

|

|

|

|

Percentage

Of Grade = |

|

Driveway

Length |

|

|

|

|

|

|

NOTE: Projection of pit may require modifications to seals and shelters.

Coordinate with supplier if required. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~ Add

items to your online shopping cart ~

Click the Price of the item you wish to

purchase. |

|

|

PRICES

FOR DH SERIES STEEL EMBED ITEMS |

| Size |

4 Piece Angle/2 Piece

Bumper Plates

Recommended |

6 Piece Angle |

3 Sided Rapid

Form Pit Kit |

4 Sided Box |

| 6' x 6' |

|

|

|

|

| Wt. |

201# |

204# |

350# |

430# |

| 6' x 8' |

|

|

|

|

| Wt. |

233# |

236# |

450# |

530# |

| 6' x 10' |

|

|

|

|

| Wt. |

262# |

265# |

615# |

695# |

| 6' x 12' |

|

|

|

|

| Wt. |

292# |

295# |

760# |

840# |

| 7' x 6' |

|

|

|

|

| Wt. |

215# |

218# |

370# |

450# |

| 7' x 8' |

|

|

|

|

| Wt. |

245# |

248# |

540# |

620# |

| 7' x 10' |

|

|

|

|

| Wt. |

277# |

280# |

720# |

800# |

| 7' x 12' |

|

|

|

|

| Wt. |

306# |

309# |

890# |

970# |

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~ Add

items to your online shopping cart ~

Click the Price of the item you wish to

purchase. |

|

|

|

| Description |

Prices |

| Hot Dip Galvanized Angles |

Consult us |

| Two (2) 11 x 20 Bumper

Plates in Lieu of Standard Height Plates |

|

| Two (2) 11 x 24 Bumper

Plates in Lieu of Standard Height Plates |

|

| Restraint Embed |

|

| Bracket Pit Floor Plate |

|

| Bumper

Mounting plate for 3 sided box |

|

| Rear Pit Spacers (Factory Install) |

| 1" & 2" |

|

| 3" & 4" |

|

| 5" & 6" |

|

| 7" & 8" |

|

| 9" & 10" |

|

| Front Angle Support |

| 1"-3" |

|

| 4" |

|

| 5" |

|

| Pit Conversions (pit depth) |

| 1" - 4" (Pit

from 19 1/2" - 23 1/2") Factory Installed |

|

| 5" - 8" |

|

| 9" - 12" |

|

| *Note may require additional freight |

| Free Standing Frame With Bumper Supports |

| 6' Long |

|

| 8' Long |

|

| 10' Long |

|

| 12' Long |

|

| *Note may require additional freight |

| Free Standing Frame (Bumpers Excluded) |

| 6' Long |

|

| 8' Long |

|

| 10' Long |

|

| 12' Long |

|

| Run

Off Guard |

|

| *Note may require additional freight |

|

| NOTE:

For 6.5' use 7' price. |

|

Specifications |

|

|

|

|

|

|

| GENERAL

DESCRIPTION: |

|

|

STANDARD

OPERATIONAL FEATURES: |

All

DH Series dock levelers incorporate the use of

hydraulics to raise and lower both the platform and

lip. A single push button activates a hydraulic pump

for operating both lip and hoist cylinders. Unit con-

forms to OSHA, U.S. Department of Commerce

Standard CS-202-56 and is manufactured in com-

pliance with the American National Standard of

Safety Performance and Testing of Dock Leveling

Devices (ANSI) MH 30.1. |

|

|

|

|

The

DH Series Leveler is controlled remotely from

wall mounted control panel. An array of optional

control panel features are available. Service range

is from 12" above to 12" below dock level. Lip

keepers welded to frame members provide night-

time security and cross-traffic support. Full operating

range toe guards are provided as standard. Mainte-

nance prop with ‘Lock-out Tag-out’ capability is

provided as standard. Factory finish includes rust

inhibitive prime coat industrial grade finish. Each

leveler is shipped with two (2) (B 410-14) 4½”

thick x 10”h x 14”w laminated bumpers as standard

on all capacities except the 60,000 CIR which gets

6” thick bumpers. |

|

|

|

| CONSTRUCTION: |

|

|

The

platform is constructed of ¼” thick 4-way high

tensile 50,000 minimum yield A572 steel safety tread-

plate (3/16” for 20,000 Comparative Industry Rating

(CIR)). Platform is reinforced and supported by full-

length roll formed “C” channels (20,000, 25,000 and

30,000 lb CIR), structural “C” channels (35,000 &

40,000 lb CIR), and a combination of structural “C”

channels and “I” beams (45,000, 50,000 and 60,000 lb

CIR). Front and rear header plate is of either ½” x 7”

or ½” x 8” hot rolled steel. DH Series lips are made

of 4-way safety treadplate, the 20,000 and 25,000 lb

CIR are 1/2” thick, the 30,000, 35,000 and 40,000 lb

CIR are 5/8” thick, and the 45,000 50,000 and 60,000 lb

CIR are 3/4” thick. The standard lip length is 16” on all

capacities except the 60,000 CIR which is 18”. Hinge

tubes are 1 3/4” OD x 5/16” wall, 1 7/8” x 3/8” wall,

2 1/8” x ½” wall, or 2 5/8” x 3/4” wall depending

upon

CIR. All lip hinge pins are 1” M1044 steel. Steel lip

gusset are standard on 50,000 and 60,000 lb CIR

models. Steel header gussets are standard on all models

35,000 lb CIR and above. All platforms are designed

to compensate for up to 4” of canted truck beds. |

|

|

|

|

|

|

|

|

ELECTRICAL: |

|

Hydraulic

pump motor shall be 1HP TEFC at 115v

single phase. Optional 3 Phase motors are available,

consult factory. Electrical control panel is a non-metallic

Nema 4 enclosure. All electrical components, connections

and wiring are UL listed or recognized. Please Note:

Unless specifically noted on quotation, all electrical

requirements are the responsibility of others. |

|

|

|

|

|

|

WARRANTY: |

|

All

DH Series models feature a full one (1) year

base warranty on all structural, hydraulic and electrical

parts, including freight and labor charge. Hydraulic

components carry an additional full one (1) year

warranty with parts and labor. Structural components

carry and additional nine (9) year pro-rated warranty.

Warrants all components to be free of defects in materials

and workmanship, under normal use, during the warranty

period. This base warranty period begins upon the

completion of installation or the sixtieth (60th) day after

shipment, whichever is earlier. Additional warranty

extensions are available upon approved submittal of

application information. |

|

|

| HYDRAULICS: |

|

Platform

is raised by an inverted hydraulic cylinder, all

hydraulic hoses are routed under the leveler platform,

away from debris. Hoist cylinder is hard chrome-plated,

single acting design with 3” OD rod and 3 ½” ID bore.

Hoist cylinder is equipped with a velocity safety stop to

limit free fall of loaded platform to 3”(±1”). Lip operation

is controlled by a hard chrome-plated cylinder having a

2 ½” ID bore and is fully yieldable. Elevated, frame

mounted pump and motor assembly keeps clear of debris

accumulation in pit. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

DLM, Dock Leveler, Dock Levelers,

Hydraulic Dock Leveler, Hydraulic Dock Plate, Loading Dock Leveler, Pit

Mount Dock

Levelers, Pit Mounted Dock Leveler, and Pit Mounted Dock Levelers from

your complete source for material handling equipment. |

|