ELECTRIC

HEATED AIR CURTAINS

|

|

| FREE

FREIGHT |

| FOR

ALL AIR CURTAINS SHIPPED TO LOCATIONS WITHIN THE 48 CONTIGUOUS UNITED STATES |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Q |

The first question is, do I really need a heated

air curtain? |

| A |

The answer is maybe not. Air doors effectively

create an efficient insulation barrier between

two environments. It's approximately 80% -

90% efficient. It does so by creating a stiff

blast of air blowing down from the unit towards

the floor. This blast of air create an invisible

barrier separating the two environments.

If you have people working near or walking

through this moving air, they may feel a breeze.

This could cause a wind chill effect, similar to

the cooling effects of a blowing fan during the

summer. Adding a heated air curtain unit will

minimize this effect and make for a comfortable

and more productive work place for your

employees and customers.

Should your facility be located in a cold weather

environment creating significant temperature

differences between the outside versus the

inside temperature, a heated unit will signi-

ficantly improve the work environment comfort

level and help maintain consistent temperature

control. In addition, it will reduce overall utility

and maintenance costs by providing a more

constant inside temperature. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

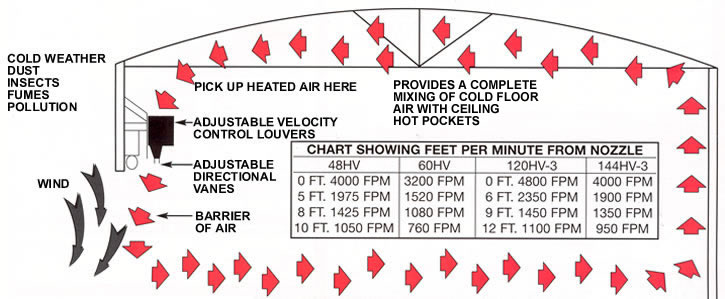

| TYPICAL

USES |

|

|

|

|

Easily

mounted over entrance ways of warehouse

doors up to 16 feet high, the air curtains direct an

invisible stream of stratified heated air downward. In

addition to adding to employee and customer comfort

during cold weather they provide important energy

savings in three ways: |

|

|

|

|

|

|

|

|

|

|

|

|

|

1.

In cold weather they reduce the load on heating

systems. By drawing warm air down to floor level

where it is needed, our air curtains utilize the 50%

of wasted heated air trapped under ceilings. Stratified

air is mixed and circulated with building heat and heat

given off by lights and machinery, etc. |

|

|

|

|

|

|

|

|

|

|

|

ENERGY |

|

|

Our

air curtains conserve energy and improve comfort by

limiting the escape of internal heat, reducing cold drafts

and providing a welcoming down flow curtain of warm

air at entrance ways in industrial plants and store buildings.

The resulting mixture of warmed air disperses gently in

all directions at floor level to give uniform temperature

over a wide area from floor to ceiling with only a few

degrees difference. |

|

|

|

|

|

|

|

2.

The high velocity curtain of air deflects winds and

reduces excessive heat loss through open doorways. |

|

|

|

|

|

|

|

|

|

3.

During warm weather they can direct a stream of air

downward to help keep dust, dirt, insects and fumes from

entering through open doorways. If air conditioning exists

in the building during warm weather, the air curtains can

be used to prevent loss of conditioned air as well. |

|

|

|

|

|

|

|

|

|

CONVENIENCE |

|

Our

air curtains allow personnel and cargo to pass freely

from one area to another while maintaining desired

temperatures. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

An

added safety feature is the free flow of traffic with an

unobstructed view through the opening, eliminating

doorway accidents. |

|

|

|

|

|

|

|

Our

air curtains create an invisible barrier of high velocity

air to stop cold or warm air infiltrating plant facilities and

work areas. |

Stop entry of cold or warm air when doors are open. Stop entry of cold or warm air when doors are open. |

|

Prevent the possibility of accidents with unobstructed Prevent the possibility of accidents with unobstructed

view of passageways. |

|

IMPORTANT:

MUST BE INSTALLED ON WARM

SIDE OF DOORWAY OPENING WHEN USED FOR

TEMPERATURE CONTROL |

Eliminate need for expensive plastic stripping, flapper Eliminate need for expensive plastic stripping, flapper

doors, or canvas curtains. |

|

Cold

weather can be further deterred at door opening if

space heater in plant is directed toward intake of the air

curtain. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| SPECIFICATIONS

AND FEATURES |

|

|

|

|

|

|

|

| FOR

ARCHITECTS AND ENGINEERS |

|

EASY

INSTALLATION |

Our

air curtains shall have a self-contained one piece

housing, fire retardant and corrosion proof, incorporated

with a double extended shaft motor, direct drive double

width and double inlet squirrel cage blower wheels and

fan housings. |

Our

air curtains are bolted to wall with four fasteners and

connected to electric power source. |

AIR

VELOCITY CONTROL FOR VARIABLE AIR

SPEED |

Shall

have wedge shaped discharge nozzle containing

adjustable air deflectors with 40% sweep front to back. |

|

Adjustable

louver damper controls are provided in order

to adjust rate of air flow. |

Housing

shall be sufficient strength for fastening to wall

on both ends without any intermediate support. |

|

When

used over a doorway to retain warm or cold

temperature, proper velocity adjustment is imperative

for maximum efficiency. Velocity Control can reduce

air velocity up to 60% with louvers in totally closed

position. |

| HEAVY

DUTY ELECTRIC MOTOR |

|

Continuous

duty type motor with double sealed lifetime

pre-lubricated stainless steel ball bearings, resilient

mounted and protected by an automatic thermal over-

load switch. Underwriters Laboratories Listed and

Canadian Standards Association Certified. Explosion

proof motors available. |

|

|

AIR

DIRECTIONAL CONTROL |

|

Adjustable

vanes at outlet nozzle for directing air

to compensate for possible draft conditions

through doorways. |

|

|

|

|

|

|

|

| FIRE

RETARDANT AND CORROSION PROOF |

|

|

|

|

|

Steel

models are of 18 gauge paint lock metal and double

protected with gray, baked, rust preventative electrostatic

polyurethane powder coating. |

|

|

|

|

How Air

Curtain Works! |

|

| NOISE

LEVEL |

|

|

|

|

|

|

|

|

|

Our

air curtains operate under a low noise level in the interest

and comfort of personnel working in the immediate vicinity. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SELECTION

TABLE |

Model

No. |

Width

of Door |

Door

Height |

FLA

(Ampacity) Single Phase |

Sound

dBA |

Weight

(lbs) |

115V |

208V/230V |

STD236 |

36" |

8'

- 10' |

5.1 |

2.5

/ 2.5 |

66 |

50 |

STD242 |

42" |

8'

- 10' |

5.1 |

2.5

/ 2.5 |

66 |

55 |

STD248 |

48" |

8'

- 10' |

5.1 |

2.5

/ 2.5 |

66 |

60 |

STD264-2 |

64" |

8'

- 10' |

10.2 |

5.0

/ 5.0 |

68 |

95 |

STD272-2 |

72" |

8'

- 10' |

10.2 |

5.0

/ 5.0 |

68 |

100 |

STD278-2 |

78" |

8'

- 10' |

10.2 |

5.0

/ 5.0 |

68 |

110 |

STD284-2 |

84" |

8'

- 10' |

10.2 |

5.0

/ 5.0 |

68 |

115 |

STD296-2 |

96" |

8'

- 10' |

10.2 |

5.0

/ 5.0 |

68 |

125 |

STD296-3 |

96" |

8'

- 10' |

15.3 |

7.5

/ 7.5 |

71 |

170 |

STD2108-2 |

108" |

8'

- 10' |

10.2 |

5.0

/ 5.0 |

71 |

130 |

STD2108-3 |

108" |

8'

- 10' |

15.3 |

7.5

/ 7.5 |

71 |

175 |

STD2120-3 |

120" |

8'

- 10' |

15.3 |

7.5

/ 7.5 |

71 |

185 |

STD2144-3 |

144" |

8'

- 10' |

15.3 |

7.5

/ 7.5 |

71 |

205 |

STD2144-4 |

144" |

8'

- 10' |

20.4 |

10.0

/ 10.0 |

73 |

215 |

HV242 |

42" |

10'

- 12' |

3.3

/ 3.2 |

1.6 |

70 |

90 |

HV248 |

48" |

10'

- 12' |

3.3

/ 3.2 |

1.6 |

70 |

95 |

HV260 |

60" |

10'

- 12' |

3.3

/ 3.2 |

1.6 |

70 |

105 |

HV272-2 |

72" |

10'

- 12' |

6.6

/ 6.4 |

3.2 |

73 |

165 |

HV284-2 |

84" |

10'

- 12' |

6.6

/ 6.4 |

3.2 |

73 |

180 |

HV296-2 |

96" |

10'

- 12' |

6.6

/ 6.4 |

3.2 |

73 |

190 |

HV296-3 |

96" |

10'

- 12' |

9.9

/ 9.6 |

4.8 |

75 |

240 |

HV2108-2 |

108" |

10'

- 12' |

6.6

/ 6.4 |

3.2 |

73 |

200 |

HV2108-3 |

108" |

10'

- 12' |

9.9

/ 9.6 |

4.8 |

75 |

255 |

HV2120-2 |

120" |

10'

- 12' |

6.6

/ 6.4 |

3.2 |

73 |

215 |

HV2120-3 |

120" |

10'

- 12' |

9.9

/ 9.6 |

4.8 |

75 |

270 |

HV2144-3 |

144" |

10'

- 12' |

9.9

/ 9.6 |

4.8 |

75 |

295 |

HV2144-4 |

144" |

10'

- 12' |

13.2

/ 12.8 |

6.4 |

75 |

375 |

|

|

|

|

|

|

|

|

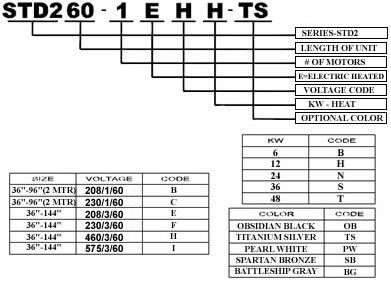

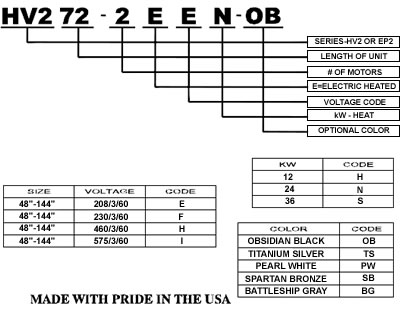

MODEL NUMBER

CONFIGURATION |

|

|

|

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~ Add

items to your online shopping cart ~

Click the Model No. of the item you wish

to purchase. |

|

|

|

|

|

|

|

| Standard

Features: |

½

hp direct-drive motor

Sleek metal design

Easy install

Motor fan assembly

18-month warranty |

Made in USA |

Standard

Color: |

|

|

|

|

|

Protection

Environmental: 10’

Flying-insects: 8’ |

|

|

|

|

|

PRICING

AND SPECIFICATIONS (ELECTRIC HEATED MODELS) |

Full

freight allowed. Prices included delivery to any destination within the

Continental United States or to Port of

Embarkation for Overseas shipments. |

|

IMMEDIATE

FREE DELIVERY MADE WITH PRIDE IN THE USA |

|

ELECTRIC

HEATED STANDARD SERIES PRICES |

Models |

Voltage |

kW |

Air

Volume

(max.) |

Length |

Height |

Depth |

Full

Load

Draw |

Wgt.

(lbs) |

Avg.

Velocity |

#

of

motors |

PRICE |

|

208/1/60 |

6kW |

1379cfm |

36" |

10

5/8" |

17

3/8" |

31amps |

90 |

2206fpm |

1 |

$2,819 |

|

230/1/60 |

6kW |

1379cfm |

36" |

10

5/8" |

17

3/8" |

29amps |

90 |

2206fpm |

1 |

$2,819 |

|

208/3/60 |

12kW |

1379cfm |

36" |

10

5/8" |

17

3/8" |

36amps |

90 |

2206fpm |

1 |

$2,819 |

|

230/3/60 |

12kW |

1379cfm |

36" |

10

5/8" |

17

3/8" |

33amps |

90 |

2206fpm |

1 |

$2,819 |

|

460/3/60 |

12kW |

1379cfm |

36" |

10

5/8" |

17

3/8" |

16amps |

90 |

2206fpm |

1 |

$2,819 |

|

208/1/60 |

6kW |

1418cfm |

42" |

10

5/8" |

17

3/8" |

31amps |

95 |

1945fpm |

1 |

$2,920 |

|

230/1/60 |

6kW |

1418cfm |

42" |

10

5/8" |

17

3/8" |

29amps |

95 |

1945fpm |

1 |

$2,920 |

|

208/3/60 |

12kW |

1418cfm |

42" |

10

5/8" |

17

3/8" |

36amps |

95 |

1945fpm |

1 |

$2,920 |

|

230/3/60 |

12kW |

1418cfm |

42" |

10

5/8" |

17

3/8" |

33amps |

95 |

1945fpm |

1 |

$2,920 |

|

460/3/60 |

12kW |

1418cfm |

42" |

10

5/8" |

17

3/8" |

16amps |

95 |

1945fpm |

1 |

$2,920 |

|

208/1/60 |

6kW |

1442cfm |

48" |

10

5/8" |

17

3/8" |

31amps |

100 |

1730fpm |

1 |

$2,957 |

|

230/1/60 |

6kW |

1442cfm |

48" |

10

5/8" |

17

3/8" |

29amps |

100 |

1730fpm |

1 |

$2,957 |

|

208/3/60 |

12kW |

1442cfm |

48" |

10

5/8" |

17

3/8" |

36amps |

100 |

1730fpm |

1 |

$2,957 |

|

230/3/60 |

12kW |

1442cfm |

48" |

10

5/8" |

17

3/8" |

33amps |

100 |

1730fpm |

1 |

$2,957 |

|

460/3/60 |

12kW |

1442cfm |

48" |

10

5/8" |

17

3/8" |

16amps |

100 |

1730fpm |

1 |

$2,957 |

|

208/1/60 |

6kW |

2700cfm |

60" |

10

5/8" |

17

3/8" |

63amps |

115 |

2592fpm |

1 |

$4,747 |

|

230/1/60 |

6kW |

2700cfm |

60" |

10

5/8" |

17

3/8" |

57amps |

115 |

2592fpm |

1 |

$4,747 |

|

208/3/60 |

12kW |

2700cfm |

60" |

10

5/8" |

17

3/8" |

72amps |

115 |

2592fpm |

1 |

$4,747 |

|

230/3/60 |

12kW |

2700cfm |

60" |

10

5/8" |

17

3/8" |

65amps |

115 |

2592fpm |

1 |

$4,747 |

|

460/3/60 |

12kW |

2700cfm |

60" |

10

5/8" |

17

3/8" |

31amps |

115 |

2592fpm |

1 |

$4,747 |

|

208/1/60 |

12kW |

2758cfm |

72" |

10

5/8" |

17

3/8" |

63amps |

180 |

2206fpm |

2 |

$5,257 |

|

230/1/60 |

12kW |

2758cfm |

72" |

10

5/8" |

17

3/8" |

57amps |

180 |

2206fpm |

2 |

$5,257 |

|

208/3/60 |

24kW |

2758cfm |

72" |

10

5/8" |

17

3/8" |

72amps |

180 |

2206fpm |

2 |

$5,257 |

|

230/3/60 |

24kW |

2758cfm |

72" |

10

5/8" |

17

3/8" |

65amps |

180 |

2206fpm |

2 |

$5,257 |

|

460/3/60 |

24kW |

2758cfm |

72" |

10

5/8" |

17

3/8" |

31amps |

180 |

2206fpm |

2 |

$5,257 |

|

208/1/60 |

12kW |

2836cfm |

84" |

10

5/8" |

17

3/8" |

63amps |

190 |

1945fpm |

2 |

$5,465 |

|

230/1/60 |

12kW |

2836cfm |

84" |

10

5/8" |

17

3/8" |

57amps |

190 |

1945fpm |

2 |

$5,465 |

|

208/3/60 |

24kW |

2836cfm |

84" |

10

5/8" |

17

3/8" |

72amps |

190 |

1945fpm |

2 |

$5,465 |

|

230/3/60 |

24kW |

2836cfm |

84" |

10

5/8" |

17

3/8" |

65amps |

190 |

1945fpm |

2 |

$5,465 |

|

460/3/60 |

24kW |

2836cfm |

84" |

10

5/8" |

17

3/8" |

31amps |

190 |

1945fpm |

2 |

$5,465 |

|

208/1/60 |

12kW |

2884cfm |

96" |

10

5/8" |

17

3/8" |

63amps |

225 |

1730fpm |

2 |

$5,584 |

|

230/1/60 |

12kW |

2884cfm |

96" |

10

5/8" |

17

3/8" |

57amps |

225 |

1730fpm |

2 |

$5,584 |

|

208/3/60 |

24kW |

2884cfm |

96" |

10

5/8" |

17

3/8" |

72amps |

225 |

1730fpm |

2 |

$5,584 |

|

230/3/60 |

24kW |

2884cfm |

96" |

10

5/8" |

17

3/8" |

65amps |

225 |

1730fpm |

2 |

$5,584 |

|

460/3/60 |

24kW |

2884cfm |

96" |

10

5/8" |

17

3/8" |

31amps |

225 |

1730fpm |

2 |

$5,584 |

|

460/3/60 |

36kW |

4137cfm |

108" |

10

5/8" |

17

3/8" |

47amps |

270 |

2206fpm |

3 |

$7,111 |

|

460/3/60 |

36kW |

4341cfm |

120" |

10

5/8" |

17

3/8" |

47amps |

280 |

2084fpm |

3 |

$7,232 |

|

460/3/60 |

36kW |

4326cfm |

144" |

10

5/8" |

17

3/8" |

47amps |

330 |

1730fpm |

3 |

$7,349 |

|

|

|

|

OB |

|

TS |

|

PW |

|

|

|

|

|

|

|

|

| Optional

Color Available - Std. Production Color is Obsidian Black (matte) See add-on prices below. |

|

|

|

|

|

|

|

Prices

for Colors That are not Standard for the Series

(add these prices to price of electric heated

standard air curtain) |

| Length of Unit |

25" |

36" |

42" |

48" |

60" |

64" |

72" |

84" |

96" |

108" |

120" |

144" |

| TS |

|

|

|

|

|

|

|

|

|

|

|

|

| PW |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Full

freight allowed. Prices included delivery to any destination within the

Continental United States or to Port of

Embarkation for Overseas shipments. |

|

IMMEDIATE

FREE DELIVERY MADE WITH PRIDE IN THE USA |

|

|

|

|

|

| Standard

Features: |

Standard Color: |

|

1

hp direct-drive motor

Sleek metal design

Easy install

Motor fan assembly

18-month warranty

Made in USA |

|

Protection

Environmental: 12’

Flying-insects: 10’ |

|

|

|

|

|

|

|

|

|

|

|

MODEL

NUMBER CONFIGURATION |

|

|

|

|

|

|

|

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~ Add

items to your online shopping cart ~

Click the Model No. of the item you wish

to purchase. |

|

|

ELECTRIC

HEATED HIGH VELOCITY MODELS PRICES |

Models |

Voltage |

kW |

Air

Volume (max.) |

Length |

Height |

Depth |

Full

Load Draw |

Wgt.

(lbs) |

Avg.

Velocity |

#

of

motors |

PRICE |

|

208/1/60 |

6kW |

2447cfm |

48" |

14" |

21

3/8" |

32amps |

145 |

2447fpm |

1 |

$3,621 |

|

230/1/60 |

6kW |

2447cfm |

48" |

14" |

21

3/8" |

29amps |

145 |

2447fpm |

1 |

$3,621 |

|

208/3/60 |

12kW |

2447cfm |

48" |

14" |

21

3/8" |

37amps |

145 |

2447fpm |

1 |

$3,621 |

|

230/3/60 |

12kW |

2447cfm |

48" |

14" |

21

3/8" |

33amps |

145 |

2447fpm |

1 |

$3,621 |

|

460/3/60 |

12kW |

2447cfm |

48" |

14" |

21

3/8" |

17amps |

145 |

2447fpm |

1 |

$3,621 |

|

208/1/60 |

6kW |

2760cfm |

48" |

14" |

21

3/8" |

32amps |

155 |

2208fpm |

1 |

$3,697 |

|

230/1/60 |

6kW |

2760cfm |

48" |

14" |

21

3/8" |

29amps |

155 |

2208fpm |

1 |

$3,697 |

|

208/3/60 |

12kW |

2760cfm |

60" |

14" |

21

3/8" |

37amps |

155 |

2208fpm |

1 |

$3,697 |

|

230/3/60 |

12kW |

2760cfm |

60" |

14" |

21

3/8" |

33amps |

155 |

2208fpm |

1 |

$3,697 |

|

460/3/60 |

12kW |

2760cfm |

60" |

14" |

21

3/8" |

17amps |

155 |

2208fpm |

1 |

$3,697 |

|

208/1/60 |

12kW |

3584cfm |

48" |

14" |

21

3/8" |

64amps |

315 |

2389fpm |

2 |

$6,879 |

|

230/1/60 |

12kW |

3584cfm |

48" |

14" |

21

3/8" |

59amps |

315 |

2389fpm |

2 |

$6,879 |

|

208/3/60 |

24kW |

3584cfm |

72" |

14" |

21

3/8" |

73amps |

315 |

2389fpm |

2 |

$6,879 |

|

230/3/60 |

24kW |

3584cfm |

72" |

14" |

21

3/8" |

67amps |

315 |

2389fpm |

2 |

$6,879 |

|

460/3/60 |

24kW |

3584cfm |

72" |

14" |

21

3/8" |

33amps |

315 |

2389fpm |

2 |

$6,879 |

|

208/1/60 |

12kW |

4644cfm |

48" |

14" |

21

3/8" |

64amps |

335 |

2654fpm |

2 |

$6,984 |

|

230/1/60 |

12kW |

4644cfm |

48" |

14" |

21

3/8" |

59amps |

335 |

2654fpm |

2 |

$6,984 |

|

208/3/60 |

24kW |

4644cfm |

84" |

14" |

21

3/8" |

73amps |

335 |

2654fpm |

2 |

$6,984 |

|

230/3/60 |

24kW |

4644cfm |

84" |

14" |

21

3/8" |

67amps |

335 |

2654fpm |

2 |

$6,984 |

|

460/3/60 |

24kW |

4644cfm |

84" |

14" |

21

3/8" |

33amps |

335 |

2654fpm |

2 |

$6,984 |

|

208/1/60 |

12kW |

4894cfm |

48" |

14" |

21

3/8" |

64amps |

340 |

2447fpm |

2 |

$7,069 |

|

230/1/60 |

12kW |

4894cfm |

48" |

14" |

21

3/8" |

59amps |

340 |

2447fpm |

2 |

$7,069 |

|

208/3/60 |

24kW |

4894cfm |

96" |

14" |

21

3/8" |

73amps |

340 |

2447fpm |

2 |

$7,069 |

|

230/3/60 |

24kW |

4894cfm |

96" |

14" |

21

3/8" |

67amps |

340 |

2447fpm |

2 |

$7,069 |

|

460/3/60 |

24kW |

4894cfm |

96" |

14" |

21

3/8" |

33amps |

340 |

2447fpm |

2 |

$7,069 |

|

460/3/60 |

36kW |

5376cfm |

108" |

14" |

21

3/8" |

50amps |

425 |

2389fpm |

3 |

$9,423 |

|

208/1/60 |

12kW |

5519cfm |

48" |

14" |

21

3/8" |

64amps |

365 |

2208fpm |

2 |

$7,223 |

|

230/1/60 |

12kW |

5519cfm |

48" |

14" |

21

3/8" |

59amps |

365 |

2208fpm |

2 |

$7,223 |

|

208/3/60 |

24kW |

5519cfm |

120" |

14" |

21

3/8" |

73amps |

365 |

2208fpm |

2 |

$7,223 |

|

230/3/60 |

24kW |

5519cfm |

120" |

14" |

21

3/8" |

67amps |

365 |

2208fpm |

2 |

$7,223 |

|

460/3/60 |

24kW |

5519cfm |

120" |

14" |

21

3/8" |

33amps |

365 |

2208fpm |

2 |

$7,223 |

|

460/3/60 |

36kW |

6693cfm |

120" |

14" |

21

3/8" |

50amps |

440 |

2678fpm |

3 |

$9,528 |

|

460/3/60 |

36kW |

7341cfm |

144" |

14" |

21

3/8" |

50amps |

465 |

2447fpm |

3 |

$9,710 |

|

|

|

|

OB |

|

TS |

|

PW |

|

|

|

|

|

|

|

|

|

| Optional

Color Available - Std. Production Color is Titanium Silver See

add-on prices below. |

|

|

|

|

|

|

|

|

|

|

Prices

for Colors That are not Standard for the Series (add

these prices to price of standard air curtain) |

| Length of Unit |

25" |

36" |

42" |

48" |

60" |

64" |

72" |

84" |

96" |

108" |

120" |

144" |

OB |

|

|

|

|

|

|

|

|

|

|

|

|

| PW |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~ Add

items to your online shopping cart ~

Click the Part No. of the item you wish to

purchase. |

|

|

|

ACCESSORIES

- Electric Heated |

|

| DOOR

SWITCHES |

| Automatic

on/off control of air curtain as door is opened and closed |

| LINE

VOLTAGE |

| Part No. |

Package |

Price |

|

Steel Mechanical

Universal Surface-Mounted Plunger/Roller Switch |

$152.90 |

| 24-Volt

Control |

|

Industrial

Floor-Mounted Magnetic Reed Switch Only - Floor mounted.

Note: Control panel required. |

$356.70 |

|

Industrial

Surface-Mounted Magnetic Reed Switch Only.

Surface-mounted.

Note: Control panel required. |

$356.70 |

|

|

| CONTROL

PACKAGES |

| Combination

packages of door switches, controllers, time delays, and thermostats |

| LINE

VOLTAGE |

| Part No. |

Package |

Price |

|

Analog

Thermostat - Remote-mounted |

$178.30 |

|

| OPTIONAL CONTROLS - Can be paired with any control package |

Part No. |

Package |

Price |

|

Master/Slave

Control with Single Thermostat |

$214.00 |

|

MOUNTING BRACKETS |

| Part No. |

Mounting Bracket |

Price |

Recommended

for specific applications · Standard color Titanium Silver

· NOTE: Units come standard with predrilled holes on back end

for flush mounting |

|

5"

Flat Side Extension Plates - to clear track

on either end - Set of 2 |

$178.30 |

|

7"

Flat Side Extension Plates - to clear track

on either end - Set of 2 |

$178.30 |

|

9"

Flat Side Extension Plates - to clear track

on either end - Set of 2 |

$178.30 |

|

2

1/2"-Clearance Adjustable-Angle Mounting Bracket To clear wall obstructions - Set of 2 |

$178.30 |

|

4"-Clearance

Adjustable-Angle Mounting Bracket To clear

wall obstructions - Set of 2 |

$356.70 |

|

7"-Clearance

Adjustable-Angle Mounting Bracket To clear

wall obstructions - Set of 2 |

$356.70 |

|

10"-Clearance

Adjustable-Angle Mounting Bracket To clear

wall obstructions - Set of 2 |

$356.70 |

|

10"-Clearance

Drum-Roll-Style Extended Wall Mounting Bracket

For use over drum-style roll-up doors - Set

of 2 |

$428.00 |

|

16"-Clearance

Drum-Roll-Style Extended Wall Mounting Bracket

For use over drum-style roll-up doors - Set

of 2 |

$428.00 |

|

19"-Clearance

Drum-Roll-Style Extended Wall Mounting Bracket

For use over drum-style roll-up doors - Set

of 2 |

$451.80 |

|

23"-Clearance

Drum-Roll-Style Extended Wall Mounting Bracket

For use over drum-style roll-up doors - Set

of 2 |

$546.90 |

|

| FILTERS |

| Part No. |

Filters |

Price |

| FLTR |

HV2 Aluminum Mesh Filter 1/4'

Internal-mount - Set of 2 - (size): Specify size in inches |

$3.40/per inch |

|

|

|

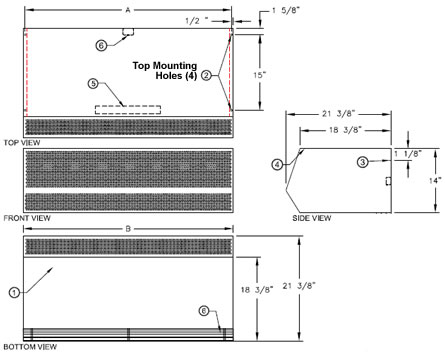

1/2

HP STANDARD HEATED MODELS DRAWING |

|

|

|

|

|

|

|

NOTES: |

|

1.

This product is designed to meet the National

Electric Code (NEC) and is ETL Listed for the

US and Canada and bear the CE Mark. |

|

2.

7/16" mounting holes (4) provided, (2) on each

end, 1/2" key hole slots (2) provided, (1)

on each

end for wall mounting. |

|

3.

All units have a self contained one piece cabinet,

fire retardant and corrosion proof paint lock metal,

double protected with baked on Obsidian Black

color rust preventative electrostatic polyurethane

powder coating. |

|

4.

Cabinet has sufficient strength for suspension

from both ends without intermediate support. |

|

5.

Control panel is prewired and premounted inside

the cabinet. Optional remote mounted available. |

|

6.

Unit is to be installed such that air flow is unob-

structed. Air discharge nozzle containing adjustable

air directional vanes with 40° sweep front to back. |

|

7.

Wall mounted 24 volt thermostat with remote"heat/

off/fan" switch shipped loose and field installed.

Terminal block provided inside panel. |

|

| 8.

Branch circuit protected as per NEC by others. |

|

9.

Optional door limit switch is field installed and is

to be wired to the control panel. Switch to be

mounted such that the air curtain turns on as door

begins to open. A time delay is highly re-

commended with the optional door limit switch. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

*NOTE: Intake screen size and number varies with unit length. |

| -2

&-3 designates the number of motors. |

|

|

|

|

|

|

|

|

|

|

Model

No. |

Mounting

Centers

A |

Length

B |

STD236-1E |

35

1/8" |

36" |

STD242-1E |

41

1/8" |

42" |

STD248-1E |

47

1/8" |

48" |

STD260-1E |

59

1/8" |

60" |

STD260-2E |

59

1/8" |

60" |

STD264-2E |

63

1/8" |

64" |

STD272-2E |

71

1/8" |

72" |

STD278-2E |

77

1/8" |

78" |

STD284-2E |

83

1/8" |

84" |

STD296-2E |

95

1/8" |

96" |

STD296-3E |

95

1/8" |

96" |

STD2108-3E |

107

1/8" |

108" |

STD2120-3E |

119

1/8" |

120" |

STD2144-3E |

143

1/8" |

144" |

STD2144-4E |

143

1/8" |

144" |

|

|

|

|

|

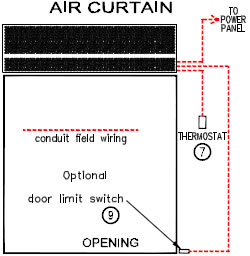

TYPICAL

INSTALLATION |

|

1.

Connect supply voltage from power panel to control panel. (8)

2. Connect wires from motor leads in junction box to terminals

in panel per print.

3. Connect wires from door limit switch to terminals in panel

per print.

4. Check rotation of motors and switch leads if necesary to

correct. |

|

|

HIGH

VELOCITY AND EXTRA POWER ELECTRIC HEATED MODELS DRAWING |

|

|

|

|

|

|

|

NOTES: |

|

1.

This product is designed to meet the National

Electric Code (NEC) and is ETL Listed for the US

and Canada and bear the CE Mark.. |

|

2.

7/16" mounting holes (4) provided, (2) on each end.

1/2" key hole slots (2) provided, (1) on each end

for

wall mounting. |

|

3.

All units have a self contained one piece cabinet,

fire retardant and corrosion proof paint lock metal,

double protected with baked on Titanium Silver

color rust preventative electrostatic polyurethane

powder coating. |

|

4.

Cabinet has sufficient strength for suspension from

both ends without intermediate support. |

|

5.

Control panel is prewired and premounted inside

the cabinet. Optional remote mounted available. |

|

6.

Unit is to be installed such that air flow is unob-

structed. Air discharge nozzle containing adjustable

air directional vanes with 40° sweep front to back. |

|

7.

Wall mounted 24 volt thermostat with remote"heat/

off/fan" switch shipped loose and field installed.

Terminal block provided inside panel. |

|

| 8.

Branch circuit protected as per NEC by others. |

|

9.

Optional door limit switch is field installed and is

to be wired to the control panel. Switch to be

mounted such that the air curtain turns on as door

begins to open. A time delay is highly recommended

with the optional microswitch. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| -2

&-3 designates the number of motors. |

|

|

*NOTE: Intake screen size and number varies with unit length. |

Model

No. |

Mounting

Centers A

| Overall

Length B

|

HV242-1E |

41

1/8" |

42" |

HV248-1E |

47

1/8" |

48" |

HV260-1E |

59

1/8" |

60" |

HV722-2E |

71

1/8" |

72" |

HV284-2E |

83

1/8" |

84" |

HV296-2E |

95

1/8" |

96" |

HV2108-2E |

107

1/8" |

108" |

HV2108-3E |

107

1/8" |

108" |

HV2120-2E |

119

1/8" |

120" |

HV2120-3E |

119

1/8" |

120" |

HV2144-3E |

143

1/8" |

144" |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

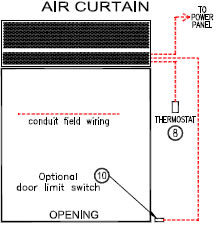

TYPICAL

INSTALLATION |

|

1.

Connect supply voltage from power panel to control panel. (9)

2. Connect wires from motor leads in junction box to terminals

in panel per print.

3. Connect wires from door limit switch to terminals in panel

per print.

4. Check rotation of motors and switch leads if necesary to

correct. |

|

|

|

|

INSTALLATION

INSTRUCTIONS FOR ELECTRIC HEATED

HIGH VELOCITY AND EXTRA POWER MODELS |

|

|

|

|

|

|

PRELIMINARY |

|

TO

INSTALL HOUSING AND

MOTOR/FAN ASSEMBLY |

|

1. Before removing

the unit from the carton, unscrew the plastic

nuts and remove the adjustable velocity control louver.

2. Remove the Motor/Fan Assembly from its carton. Industrial

models have the motor/fan assembly(s) shipped separately.

Be careful not to touch the dynamically balanced wheels

or

damage the electric heating elements when removing

the motor/

fan assembly from the box.

3. Remove the housing from the carton.

WARNING: TO REDUCE THE RISK OF FIRE, ELECTRIC

SHOCK OR INJURY TO PERSONS, OBSERVE THE

FOLLOWING:

A. Installation

work or electrical wiring must be done by

qualified person(s) in accordance with all applicable codes

and standard, including fire-rated construction.

B. The combustion

airflow needed for safe operation of fuel

burning equipment in the area may be affected by the

unit's operation. Follow the heating equipment manu-

facturer's guideline and safety standards, such as those

published by the National Fire Protection Association

(NFPA), the American Society of Heating, Refrigeration

and Air Conditioning Engineers (ASHRAE) and local code

authorities.

C. When cutting

or drilling into a wall or ceiling, be careful

not to damage electrical wiring and other hidden utilities. |

|

1. Measure the housing,

and then center it on the wall over the

doorway opening. See Table I for the minimum clearance

required on the panel side of the unit for access

and service.

2. Spot holes through 7/16" mounting holes. (2) on each end

of the housing. If necessary, drill extra holes in

the back of

the housing to align with stud spacing. (See Figure

1)

3. Mount the unit with the discharge nozzle 1" above the door

opening. If the unit is mounted higher, move it 3/8"

away from

the wall for every 1" it is moved up above the

door. Any void

between wall and unit must be sealed for optimum performance.

Threaded rods may be used for overhead installation.

4. Use all four mounting holes when installing the housing.

5. When mounting multiple units side by side, allow no more

than 6" between the units. Master/Slave configuration

required to allow the units to operate simultaneously.

(Single T'stat Control) (see figure 2)

6. Replace Motor/Fan Assembly(s) in the housing and secure

with wingnuts. Connect all motor(s) and electric heater(s)

connections.

7. Replace the intake louver or inlet screen and fasten with the

hex nuts.

8. Connect panel to proper voltage. Check the motor rotation.

(See Figure 1) |

|

|

|

|

|

|

|

|

|

|

|

TABLE

1 |

|

ADJUSTMENTS |

|

|

Model

No. |

Motor

HP |

Number

of

Motors |

Mounting Centers

A |

Min. Panel Clearance Req'd (B) |

| HV248-1E |

1 |

1 |

47 1/8" |

17" |

| HV260-1E |

1 |

1 |

59 1/8" |

17" |

| HV272-2E |

1 |

2 |

71 1/8" |

21" |

| HV284-2E |

1 |

2 |

83 1/8" |

21" |

| HV296-2E |

1 |

2 |

95 1/8" |

21" |

| HV2120-2E |

1 |

2 |

119 1/8" |

21" |

| HV2120-3E |

1 |

3 |

119 1/8" |

21" |

| HV2144-3E |

1 |

3 |

143 1/8" |

21" |

|

|

|

|

|

1. Pull

air directional vanes in air discharge nozzle to proper

position with air flow slated slightly outward around

15°.

2. Set air velocity control louvers so that the air stream just

reaches the floor to prevent turbulent mixing of inside

and

outside air.

3. The unit is to be installed such that the airflow is unobstructed.

4. The thermostat should be mounted such that it senses the

room temperature. Do not mount thermostat on a cold wall,

below a discharge grill or in direct sunlight. The high

limit

switches may trip, shutting off the heat, if improperly

installed. |

|

|

|

NOTE: MODEL NUMBER DESIGNATES THE LENGTH OF THE

UNIT IN INCHES, WHICH IS DENOTED AS "L". ALL

DIMENSIONS ARE IN INCHES. |

|

|

|

|

|

|

|

|

|

|

CONTROL

PANEL INSTALLATION |

|

A.

Connect supply voltage from power panel to control panel. Circuit protection

as per NEC by others.

B. Connect motor and heater leads to leads from the control panel and connect

thermostat to terminals in panel per print.

C. Connect wires from microswitch to terminals in control panel per print.

D. Check rotation of blower wheels. Switch leads if necessary to correct.

E. The door microswitch has normally closed contacts. The contacts open

when the door shuts depressing the plunger, turning the Air

Curtain off. |

|

|

TYPICAL

INSTALLATION OF METAL AIR CURTAINS

FOR DRUM TYPE ROLL-UP DOORS |

|

|

|

TYPICAL

INSTALLATION FOR VERTICAL LIFT TRACK DOORS |

|

|

|

|

TYPICAL

INSTALLATION FOR OVERHEAD MOUNTING |

|

|

|

|

|

|

|

Electric Heated Air Curtains,

Air Curtain, Air Curtain Door, Air Curtain Heater, Air Curtains, Air Doors,

Door Air Curtains, Heat

Curtains, Mars Air Curtain, Mars Air Door, Warm Air Curtains, and Insect

Barrier from your source for material handling equipment. |

|