LAPEYRE®

STAIRS

|

|

|

|

|

|

|

|

|

|

|

|

ALTERNATING

TREAD

|

|

|

|

|

|

|

|

|

|

|

|

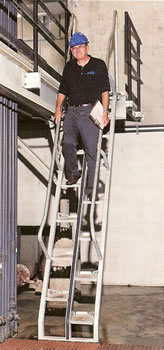

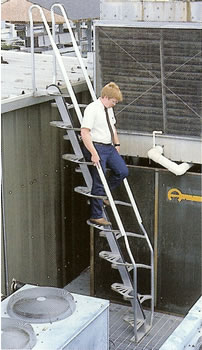

The

Lapeyre® stair is safer than vertical ladders and ships ladders |

|

|

|

|

|

|

|

|

|

|

|

STEEL

STAIRS

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Materials

& Finishes:

Carbon Steel

• Safety Yellow Powder Coat

• Gray Primer Powder Coat

• Iron Gray Powder Coat

• 180 additional Powder Coat Colors available

• Hot Dip Galvanized

Stainless Steel

• Natural

Finish

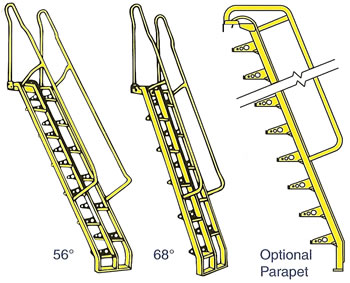

Heights: Custom Height built

56 Degree

• 36" to

240"

68 Degree

• 42" to 240"

A flush or an optional 5.75" handrail is available

for roof hatch applications. |

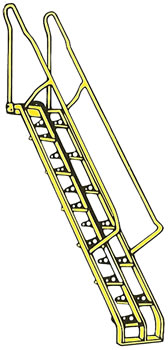

The

Lapeyre® stair features a unique alternating

tread design which provides greater tread depth

than vertical ladders or ship's ladders. This design

allows comfortable face forward descents at steep

angles. The stair includes close fitting handrails

which provide support and a cushioned central

stringer which virtually eliminates the possibility of

hitting the nosing of a tread. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

56°

AND 68° STEEL |

|

|

SEE

BELOW FOR PRICES |

|

|

|

ALUMINUM

STAIRS

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The Lapeyre® aluminum

alternating tread stair combines the safety features of

our unique, alternating tread design with the advantages aluminum has

to offer.

Aluminum is ideal for exterior applications and for applications where

weight is

a consideration. The cast aluminum treads are welded to the central stringer

and

to the handrails, creating an all-in-one welded unit. An optional 3.75"

handrail

is available for roof hatch applications. |

|

|

|

|

|

|

|

|

|

|

|

Materials

& Finishes:

Aluminum

• Natural Finish

Heights:

Custom Height built

68 Degree

• 24" to 216" |

|

|

|

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~ Add

items to your online shopping cart ~

Click a Price of the item you wish to purchase. |

|

|

PRICES

FOR STEEL AND ALUMINUM STAIRS |

VERTICAL

RISE |

PROJECTIONS SHOWN

IN INCHES FOR: |

Carbon Steel

Yellow or Iron

Gray Powder

Coat Finish

56/68 Degree |

Carbon Steel

Hot-Dip

Galvanized

56/68

Degree |

*Carbon Steel

Choice of

Color

Powder

Coat 56/68

Degree |

Aluminum

Natural

Finish

68 Degree |

Stainless Steel

Natural Finish

56/68 Degree |

| IN |

IN |

56 DEGREE |

68

DEGREE |

68

DEGREE |

| FEET |

INCHES |

STEEL |

STEEL |

ALUMINUM |

| 2 |

24 |

N/A |

N/A |

15.86 |

N/A |

N/A |

N/A |

|

N/A |

| 2.5 |

30 |

N/A |

N/A |

18.49 |

N/A |

N/A |

N/A |

|

N/A |

| 3 |

36 |

28.93 |

N/A |

20.31 |

|

|

$1,904.95 |

|

|

| 3.5 |

42 |

33.11 |

23.08 |

22.97 |

|

|

$2,083.57 |

|

|

| 4 |

48 |

37.25 |

25.66 |

25.56 |

|

|

$2,262.18 |

|

|

| 4.5 |

54 |

41.37 |

28.2 |

28.1 |

|

|

$2,440.80 |

|

|

| 5 |

60 |

44.91 |

30.28 |

30.18 |

|

|

$2,619.42 |

|

|

| 5.5 |

66 |

49.07 |

32.83 |

32.73 |

|

|

$2,798.03 |

|

|

| 6 |

72 |

53.21 |

35.36 |

35.26 |

|

|

$2,976.65 |

|

|

| 6.5 |

78 |

57.33 |

37.86 |

37.76 |

|

|

$3,155.26 |

|

|

| 7 |

84 |

61.44 |

40.04 |

39.94 |

|

|

$3,333.88 |

|

|

| 7.5 |

90 |

65.15 |

42.56 |

42.46 |

|

|

$3,512.49 |

|

|

| 8 |

96 |

69.27 |

45.05 |

44.95 |

|

|

$3,691.11 |

|

|

| 8.5 |

102 |

73.39 |

47.28 |

47.18 |

|

|

$3,869.72 |

|

|

| 9 |

108 |

77.49 |

49.78 |

49.68 |

|

|

$4,048.34 |

|

|

| 9.5 |

114 |

81.59 |

52.27 |

52.17 |

|

|

$4,226.95 |

|

|

| 10 |

120 |

85.38 |

54.75 |

54.65 |

|

|

$4,405.57 |

|

|

| 10.5 |

126 |

89.49 |

57.01 |

56.91 |

|

|

$4,584.18 |

|

|

| 11 |

132 |

93.59 |

59.5 |

59.4 |

|

|

$4,762.80 |

|

|

| 11.5 |

138 |

97.68 |

61.98 |

61.87 |

|

|

$4,941.42 |

|

|

| 12 |

144 |

101.77 |

64.45 |

64.35 |

|

|

$5,120.03 |

|

|

| 12.5 |

150 |

105.62 |

66.74 |

66.64 |

|

|

$5,298.65 |

|

|

| 13 |

156 |

109.71 |

69.21 |

69.11 |

|

|

$5,477.26 |

|

|

| 13.5 |

162 |

113.8 |

71.68 |

71.58 |

|

|

$5,655.88 |

|

|

| 14 |

168 |

117.89 |

73.98 |

73.88 |

|

|

$5,834.49 |

|

|

| 14.5 |

174 |

121.97 |

76.45 |

76.35 |

|

|

$6,013.11 |

|

|

| 15 |

180 |

125.85 |

78.92 |

78.82 |

|

|

$6,191.72 |

|

|

| 15.5 |

186 |

129.94 |

81.38 |

81.28 |

|

|

$6,370.34 |

|

|

| 16 |

192 |

134.02 |

83.7 |

83.6 |

|

|

$6,548.95 |

|

|

| 16.5 |

198 |

138.11 |

86.16 |

86.06 |

|

|

$6,727.57 |

|

|

| 17 |

204 |

142.19 |

88.62 |

88.52 |

|

|

$6,906.18 |

|

|

| 17.5 |

210 |

146.09 |

91.08 |

90.98 |

|

|

$7,084.80 |

|

|

| 18 |

216 |

150.17 |

93.41 |

93.31 |

|

|

$7,263.42 |

|

|

| 18.5 |

222 |

154.25 |

95.87 |

N/A |

|

|

$7,442.03 |

N/A |

|

| 19 |

228 |

158.33 |

98.33 |

N/A |

|

|

$7,620.65 |

N/A |

|

| 19.5 |

234 |

162.4 |

100.78 |

N/A |

|

|

$7,799.26 |

N/A |

|

| 20 |

240 |

166.32 |

103.12 |

N/A |

|

|

$7,977.88 |

N/A |

|

|

| *Contact

us for Optional Color Charts. |

|

SAFETY

GATES

|

|

|

|

|

|

If

you have been searching for a way to provide add-

itional safety at the top of your alternating tread stair,

we now have the answer. Our new safety gate attaches

to the top rails of our alternating tread stairs. This is the

first gate designed with the dimensions and connections

needed to provide a perfect fit on an alternating tread

stair. Completely reversible, the gate swings 180° and

has several installation options. It attaches to the stair

handrails or to the platform at the top of the stair. You

will only find this model gate by calling Lapeyre Stair

as it is manufactured exclusively for us by PS Doors.

Specifications:

• Mounting Bracket: PS DOORS standard, exclusive

Universal Pivot Clamp Bracket to fit railings up to 2"

OD.

• Hinge Plate: Mounting holes for reversible swing

adjustment.

• Hinge

Springs: Torsion type, stainless steel. Provide

two (2) springs per gate, housed within hinge pivot.

• Gate

Arm: Formed

1-1/4" square, 11 gauge steel

tubing with center rail.

• Material Finishes:

-Carbon Steel, on all

exposed surfaces. Choose

from options below:

1. Powder Coat Safety Yellow. Fasteners to

be

zinc plated.

2. Hot Dip Galvanized. Fasteners to

be zinc plated.

-Stainless Steel, grade 304, mill finish, acid washed and

rinsed after fabrication, interfering welds are

ground,

not polished. Fasteners to be stainless steel.. |

|

|

|

|

|

|

|

|

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~ Add

items to your online shopping cart ~

Click a Price of the item you wish to purchase. |

|

|

| MODEL NUMBER |

Shipping Weight |

Unit Price |

| LSG-3-18-GAL |

24 lbs |

|

| LSG-3-18-PCY |

24 lbs |

|

| LSG-3-18-SST |

24 lbs |

|

|

|

|

|

Dimensions:

• Gate Width: 18"

• Overall

Vertical Height: 30-1/4"

Gate Operation:

• Allows for 180° travel.

• Gate swing is reversible by

repositioning Gate

Hoop on Hinge Plate. |

Finish

Identifier:

GAL = Galvanized

PCY = Powder Coat Safety Yellow or Gray Primer

SST = Stainless Steel |

|

|

|

|

|

|

INSTALLATION

DETAILS |

1.

When ordering, specify the change in elevation (H) between the upper finished

floor surface where the top landing will

attach (A) and the lower finished floor

surface where the foot of the stair will be

secured (B). Be sure to take into account

the effects of a slopping lower floor. |

|

2.

A minimum of 6" (15.24 cm) should be

provided between the handrails and any

other object (a minimum of 12" (30.48 cm)

between handrails on two adjacent stairs).

More than 6" (15.24 cm) is preferred to

allow easier carrying of small objects out-

side the handrails. |

|

3. Always install

the stair with the top

tread at same elevation as the upper

finished floor or roof surface. For wall

parapets, contact us.

4. The stair is secured

in place by bolts

(not included) at top and bottom. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SPECIFICATIONS |

|

|

SECTION

05517 - ALTERNATING TREAD STEEL STAIRS

PART

1 - GENERAL

1.1 RELATED DOCUMENTS:

Drawings and general provisions of Contract, including General

and Supplementary Conditions and Division-1 Specification

sections, apply to work of this section.

1.2 SUMMARY:

A. Provide all material, labor, equipment and services and perform

all operations necessary or required for the work of this section,

in accordance with the Drawings and Specifications, and including fabrication

and installation of Alternating Tread Steel Stairs.

B. Related work specified elsewhere includes but is not limited to:

1. Conventional Metal Stairs in another Division 5 section

2. Metal Fabrications in another Division 5 section

3. Painting in Division 9

1.3 PERFORMANCE REQUIREMENTS:

A. Stair Treads: shall be capable of withstanding a single

concentrated 1000 pound load without permanent deformation.

B. Handrail: shall be capable of withstanding a single

concentrated load of 200 pounds or a uniform load of 50 pounds

per linear foot applied in any direction at any point on the rail.

1.4

CONSTRUCTION REQUIREMENTS:

A. Landings,

Treads, and Mounting Base: shall be stamped

and formed from single piece material. Stock shapes, hand forming,

or welded remnants shall not be permitted. All stamped parts

shall have integrally formed rigidizing bends and shall be spot

welded to stringers of like material.

B. Welds: shall be a minimum of 6 welds per tread, and 12 welds

each on the landing and footing. Each weld shall be quality

controlled and be capable of withstanding a minimum of

2800 lbs. in shear.

C. Pedestrian Surfaces: shall be punched through with upset

non-skid openings.

D. Riser Spacing: shall be equally spaced to within 3/16" for

adjacent risers and to within 3/8" for any two non-adjacent

risers on a stair.

E. Handrails: shall be contoured for body guidance and underarm

support and shall be attached to the outside stringers and

landings by bolting.

F. Landing Reinforcement: shall be with minumin .20" (0.51 cm)

steel formed angle notched and punched and factory welded to

the landing at the points of a handrail attachment.

G. Rubber Foot Divider: shall be affixed to the central portion

of the landing. A rubber bumper strip shall be attached or will be

provided for field attaching to the central stringer.

1.5

DIMENSIONS:

A. Stair Angle:

[56] or [68] degrees from horizontal as specified

in the drawings.

B. Vertical Drop: the change in elevation, as shown in the drawings,

between the upper finished floor surface where the top landing

will be attached and the lower finished floor surface where the

base of the stair will be secured.

1.6

SUBMITTALS:

Dimensional Prints: shall be submitted for approval prior to

fabrication.

PART 2- PRODUCTS

B. Substitutions will not be considered.

2.2

MATERIALS:

A. Carbon Steel:

1. Treads: 13 Gauge 1010/15 HRPO per ASTM A569

2. Landing & Foot Stampings: 11 Gauge 1010/15 per ASTM A569

3. Stringers:

a. 2" x 1 3/4" x 11 Gauge 1010/15 per ASTM A569 for 56 degree

stairs under 10 vertical feet and for 68 degree stairs under 12

vertical feet.

b. 3" x 1 3/4" x 11 Gauge 1010/15 for 56 degree stairs over

10

vertical feet and for 68 degree stairs over 12 vertical feet.

4. Handrails: 1 1/2" OD x 0.083" 1010/15 CS per ASTM A569

cold drawn, fully annealed tube per ASTM 513.

B. Stainless Steel:

1. Treads: 13 Gauge 304 SS

2. Landing & Foot Stampings: 11 Gauge 304 SS

3. Stringers:

a. 2" x 1 3/4" x 11 Gauge 304 SS for 56 degree stairs under

10

vertical feet and for 68 degree stairs under 12 vertical feet.

b. 3" x 1 3/4" x 11 Gauge 304 SS 56 degree for stairs over 10

vertical feet and for 68 degree stairs over 12 vertical feet.

4. Handrails: 1 1/2" OD x 0.065" 304 SS cold drawn, fully

annealed tube per ASTM A513.

C. Miscellaneous Material:

1. Rubber Spine: Hollow neoprene

2. Rubber Foot Divider: Solid neoprene

2.3

FINISHES:

A. Carbon Steel:

1. Safety Yellow Paint: Powder Coat Baked Enamel or

2. Hot-Dip Galvanized: per ASTM A123

B. Stainless Steel: Natural finish

2.4

FABRICATION:

General: Fabricate alternating tread steel

stairs to conform with performance and construction

requirements, and in accordance with approved shop drawings

or dimensional prints. Fabricate and shop-assemble to greatest

extent possible.

A. Carbon Steel: gas metal arc welded with treads spot welded to stringers

and bolt-on handrails with included bolts using the

specified materials.

B. Stainless Steel: gas tungsten arc welded and/or gas metal

arc welded with treads spot welded to stringers and bolt-on

handrails with included bolts using the specified materials.

PART

3- EXECUTION:

3.1 PREPARATIONS:

A. Coordination:

Coordinate start and installation of steel

alternating treads with all other related and adjacent work.

Installation shall not start until the construction

has progressed to the point that weather conditions and

remaining construction operations will not damage stair

installation.

B. Verification: Verify that dimensions and angle are correct

and that substrate is in proper condition for stair installation.

Do not proceed to install until all necessary corrections have

been made.

3.2

INSTALLATION:

A. If bumper

has not been installed at the factory, install the self adhesive bumper.

B. Prepare mounting holes.

C. Position stair with top tread at same elevation as upper

finished floor or roof surface.

D. Secure stair with not less than 2 bolts or studs at top and

with not less than 2 at bottom of stair.

E. Touch up with matching paint any chipped or abraded

damage to factory finish or

F. Touch up any damage to galvanized surfaces using

galvanized repair paint in accordance with ASTM A780.

3.3

CLEAN:

Leave work area clean and free of debris. |

SECTION

05 51 6- ALTERNATING TREAD ALUMINUM STAIRS

PART 1- GENERAL

1.1

RELATED DOCUMENTS:

Drawings and

general provisions of Contract, including General

and Supplementary Conditions and Division-1 Specification

sections, apply to work of this section.

1.2

SUMMARY:

A. Provide

all material, labor, equipment and services and

perform all operations necessary or required for the work of this section,

in accordance with the Drawings and Specifications,

and including fabrication and installation of Alternating Tread

Aluminum Stairs.

B. Related work specified elsewhere includes but is not limited to:

1. Conventional Metal Stairs in another Division 5 section

2. Metal Fabrications in another Division 5 section

1.3

PERFORMANCE REQUIREMENTS:

A. Stair Treads: shall be capable of withstanding a concentrated

1000 pound load without permanent deformation..

B. Handraisl: be capable of withstanding a load of 200 pounds

applied in any direction at any point on the rail.

1.4

CONSTRUCTION REQUIREMENTS:

A. Cast Aluminum

Treads, Landings, and Mounting Base: shall be shielded metal arc welded

to a single extruded box-like stringer.

B. Tread Castings: shall have integrally cast handrail support arms which

are precision machined and welded to continuous aluminum handrails.

C. Pedestrian Surfaces: shall be cast with skid resistant surfaces

and all treads shall have upturned integrally cast skid barriers.

D. Riser Spacing: shall be equally spaced to within 3/16" for

adjacent and to within 3/8" for any two non-adjacent risers on

a stair.

E. Handrails: shall be contoured for body guidance and underarm support,

and shall have inclined hand side portions for free

sliding of the hands unimpeded by the handrail supports.

F. Cast Aluminum Foot Divider: shall be an integral part of the

landing and shall form a support for a rubber bumper strip that

shall be attached to the central stringer.

1.5

DIMENSIONS:

A. Stair Angle: 68 degrees from horizontal

B. Vertical Drop: the change in elevation, as shown in the

drawings, between the upper finished floor surface where the

top landing will be attached and the lower finished floor surface

where the foot of the stair will be secured.

1.6 SUBMITTALS:

Dimensional prints shall be submitted for approval prior

to fabrication.

PART

2-PRODUCTS

B. Substitutions

will not be considered.

2.2

MATERIALS:

A. Landings, Treads and Foot Castings: Aluminum alloy F356F

B. Handrails:

1. Aluminum Alloy 6063-T4 per ASTM B221

2. 1-1/2" x 1/8" Tube

C. Central Stringer:

1. Aluminum Alloy 6063-T52 per ASTM B221

2. 1-3/4" x 4" x 1/8" Box Shape

D. Miscellaneous Materials:

1. Rubber Spine: Hollow neoprene strip

2.3

FINISH: Natural

Finish

2.4

FABRICATION:

A. General:

Fabricate alternating tread aluminum stairs to

conform with performance and construction requirements,

and in accordance with approved shop drawings or

dimensional prints. Fabricate and shop-assemble to greatest

extent possible.

B. Fabricate gas metal arc welded and/or gas tungsten arc welded alternating

tread aluminum stairs using the specified materials.

PART 3- EXECUTION:

3.1

PREPARATIONS:

A. Coordination: Coordinate start and installation of aluminum alternating

treads with all other related and adjacent work.

Installation shall not start until the construction has progressed

to the point that weather conditions and remaining construction

operations will not damage stair installation.

B. Verification: Verify that dimensions and angle are correct

and

that substrate is in proper condition for stair installation. Do not

proceed to install until all necessary corrections have been made.

3.2

INSTALLATION:

A. Prepare

mounting holes.

B. Position stair with top tread at same elevation as upper

finished floor or roof surface.

C. Secure stair with not less than 2 bolts or studs at top and

with not less than 2 at bottom of stair.

3.3

CLEAN:

Leave

work areas clean and free of debris. |

|

|

Lapeyre Stairs, Alternating

Tread, Steel Stiars, Alternating Tread Design, Close Fitting Handrails,

Stainless Steel,

Aluminum Stairs, and Alternating Tread Stair from your complete source

for material handling equipment. |

|