WALK-IN

SYSTEM

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| WALK-IN

SYSTEM |

|

|

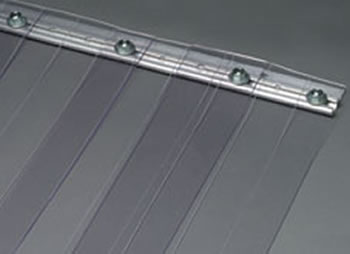

Designed

for easy installation, simply center the aluminum slotted

extrusion bar just above the doorway opening on the inside wall

of your walk-in with the lag screws provided. Slide the carriage

bolts provided into the slot and begin hanging the pre-punched

strips on either the extreme left or right side of the bar, securing

the strips with the washers and nuts provided as you progress. |

|

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~ Add

items to your online shopping cart ~

Click a Part No. of the item you wish to

purchase. |

|

|

|

|

|

|

|

|

|

|

|

| PRICING

FOR WALK-IN SYSTEM |

|

|

|

|

|

|

|

|

|

| Mounting: Walk-in Aluminum Only. |

|

|

|

|

|

|

|

|

|

|

|

|

|

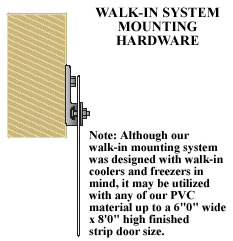

Strip

Width and Thickness: 4" x .060

Strip Type: Standard/Smooth

Overlap (Inches/%): 1"/50% |

|

Strip

Width and Thickness: 6" x .060

Strip Type: Cooler/Smooth

Overlap (Inches/%): 2"/66% |

|

Strip

Width and Thickness: 8" x .080

Strip Type: Cooler/Smooth

Overlap (Inches/%): 2"/66% |

|

|

|

|

|

|

|

|

|

| Part # |

Door Size W x H |

Prices |

|

2' x 3' |

$131 |

|

2' x 4' |

$118 |

|

2' x 5' |

$133 |

|

3' x 3' |

$178 |

|

3' x 4' |

$214 |

|

3' x 5' |

$249 |

|

4' x 3' |

$236 |

|

4' x 4' |

$286 |

|

4' x 5' |

$331 |

|

5' x 3' |

$279 |

|

5' x 4' |

$346 |

|

5' x 5' |

$405 |

|

|

|

|

| Part # |

Door Size W x H |

Prices |

|

3' x 7' |

$165 |

|

4' x 4' |

$151 |

|

4' x 7' |

$220 |

|

5' x 7' |

$271 |

|

|

|

| Part # |

Door Size W x H |

Prices |

|

3' x 7' |

$144 |

|

6' x 7' |

$270 |

|

7' x 7' |

$314 |

|

3' x 8' |

$158 |

|

6' x 8' |

$296 |

|

7' x 8' |

$347 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Walk-In

System Installation Instructions |

|

|

|

|

|

|

|

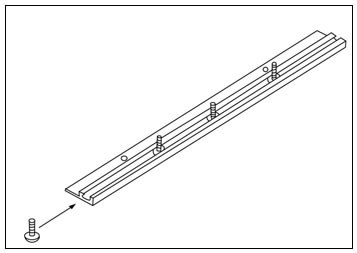

Diagram

1 |

|

|

TOOLS NEEDED |

|

Mount

Bracket |

|

•

Pen or Pencil to Mark Holes

• Drill

• Crescent Wrench

• Step Stool or Ladder

• Utility Knife to Cut Strips |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

IMPORTANT |

|

|

|

Prior

to installation, unroll all door strips and place them

on a clean, flat surface in a warm atmosphere for a minimum

of twenty-four (24) hours. This will allow the strips to return

to their original form. |

|

|

|

|

|

|

|

|

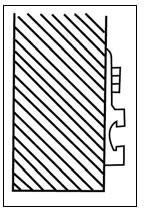

1.

Mount pre-drilled Walk-In Mount to wall above door. |

|

|

|

|

Use fasteners supplied by others for mounting

(Diagram 1). |

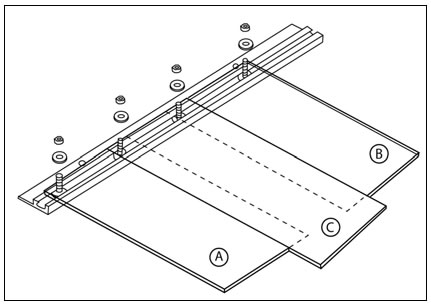

| Diagram

2 |

|

|

|

| Install

Carriage Bolts |

|

|

|

|

|

|

|

|

|

2.

Next, slide all the 3/8” carriage bolts down the slot of |

|

|

aluminum mounting

hardware (Diagram 2). |

|

|

|

|

3.

Starting at the left, place the first clear inside strip (A) |

|

|

on the first two

bolts keeping in mind the concave

pattern in Diagram 4 below. Place the second inside

strip (B) on the third and fourth bolts and continue

down the entire length accordingly (Diagram 3). |

|

|

|

|

4.

Again starting at the left and using the concave pattern, |

|

|

place the first

outside strip (C) on the second and third

bolts. The next outside strip will fit on the fourth and fifth

bolts. Continue this down the entire length accordingly

(Diagram 3). |

|

|

|

|

|

|

|

| Diagram

3 |

|

5.

Place all washers and bolts onto screws |

|

|

and

tighten finger tight (Diagram 3). |

|

|

|

|

|

|

|

6.

The first strip on left is to be flush with the |

|

|

edge of the aluminum

hardware. Starting at

this point with the nut, tighten securely with

tool. Next, take second nut in hand and pull to

the right to secure the strip flat against the

aluminum hardware. Tighten second nut with

tool. Continue this pattern until all strips are

flat and smooth and all bolts are securely tight. |

|

|

|

|

7.

The strips should be initially trimmed to |

|

|

give a minimum

of ¼” clearance using a

utility knife. The door strips need to

hang for 24 to 28 hours before the

final trim to allow for proper alignment. |

|

|

|

|

Diagram

4 |

|

|

|

|

|

|

|

|

|

|

|

Walk-In System, Aleco Strip

Doors, Plastic Strip Door, PVC Strip Door, Strip Door, Strip Doors, Vinyl

Strip Door, Welding Strip,

Truck Mount Strip Door, Insect Barrier, and Traffic Doors from your source

for material handling equipment. |

|