|

WHISPURR

AIR (UNHEATED)

|

|

|

|

|

|

|

|

|

|

|

|

ENERGY

SAVING AIR CURTAIN

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

LOW

PROFILE AIR CURTAIN FOR COMMERCIAL APPLICATIONS

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CUSTOMER

ENTRANCE DOOR

|

|

PASS-THROUGH

WINDOW

|

|

WALK-IN

FREEZER

|

|

|

|

|

|

|

|

|

|

|

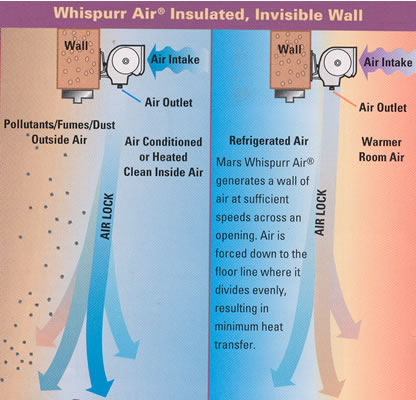

Air

curtains prevent air from entering a conditioned environment

such as a heated or air conditioned room. By

generating an evenly distributed laminar air flow over

an entryway, air curtains seal in heated or refrigerated

air and

repel wind borne contaminants such as dust, fumes and

pollutants. Save energy by preventing air conditions.

Whispurr Air® air curtains provide an ideal, cost-effective

solution in places where an entrance door or service

window is continually in use or left open for extended

periods of time. |

|

|

|

|

|

|

|

|

|

|

| Whispurr

Air® air curtains must be installed inside heated

or air conditioned buildings. |

|

|

|

|

|

|

|

|

|

|

|

•

Simple, fast installation

• 7 1/2" Low profile design ideal for restricted

ceiling height

• Specially formulated PolyMars® housing

material

• Variable air velocity and directional controls

• Low sound level while maintaining high air

velocity

• Largest unit (6') weights less than 28 pounds

• Custom colors available - white is standard

• Air Doors air curtain - proudly made in the

USA since 1962

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

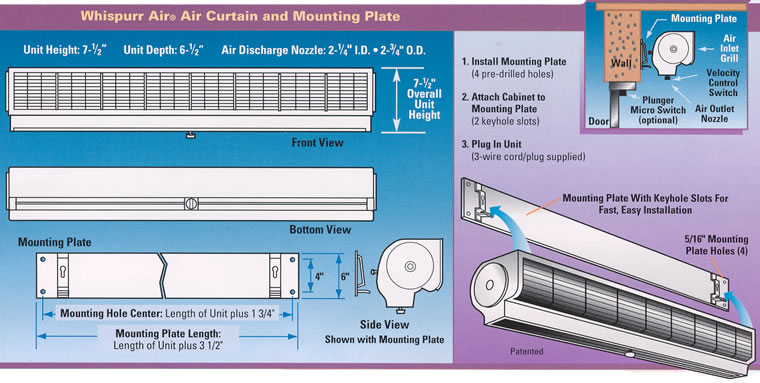

Installation

example:

school cafeteria serving door.

|

|

Adjustment

of air flow for

dust, pollutants and fumes.

|

Adjustment

of air flow for

climate control, coolers and

freezers.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Voltage

must be specified when ordering. |

|

Standard

Features: All units

have a variable air velocity

control switch with on/off

operation. Standard

production color is white. |

|

|

|

|

|

| Model

number designates length of unit in inches. |

|

|

| All

models listed below have high impact polymars housings.

Production Color: White |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Whispurr

Air Models - Installed over customer entrance doors

with ceiling as low as 8 inches to top of door header.

Also mounted over Walk-in Coolers, Freezers and pass

through Windows. Add Micro Switch if needed for automatic

on/off control. |

|

|

|

|

|

|

PRICING

AND SPECIFICATIONS (UNHEATED

MODELS)

|

|

Model No. |

Length |

Max Ft per Minute at Nozzle |

Max Cubic Ft per Minute |

Amps Single Phase |

Sound Level dBA Measured 10 Ft. from Nozzle |

Door Heights |

Weight |

Price |

|

115V |

230V |

|

WA 36 |

36" |

1800 |

900 |

2.4 |

0.9 |

49 |

Up to 7' |

16 lbs |

$726.00 |

|

WA 42 |

42" |

1800 |

1050 |

2.4 |

0.9 |

50 |

Up to 7' |

19 lbs |

$759.00 |

|

WA 48 |

48" |

1800 |

1200 |

2.4 |

0.9 |

52 |

Up to 7' |

22 lbs |

$792.00 |

|

WA 60 |

60" |

1800 |

1500 |

2.6 |

1.3 |

52 |

Up to 7' |

25 lbs |

$825.00 |

|

WA72 |

72" |

1800 |

1800 |

2.6 |

1.3 |

53 |

Up to 7' |

28 lbs |

$1,045.00 |

|

| Note:

No control panel is needed for Whispurr Air Series. |

|

| Options

|

|

Door

Micro Switch for automatic on/off control. Activates

air curtain when door is opened, turns off when door

is closed |

|

| TZ6112

Combination Micro Switch (Both Plunger/Roller all

in one)..........$66.00 |

|

| Walk-in

Installation Kit (with transformer & Magnetic

Switch).................$165.00 |

|

|

WA

Whispurr Air Low Profile Commercial Models

|

|

|

|

Model No. |

Overall Length (A) |

Nozzle Length (B) |

Mount Plate Length (C) |

|

WA 36 |

36 1/2" |

36" |

39 1/2" |

|

WA 42 |

42 1/2" |

42" |

45 1/2" |

|

WA 48 |

48 1/2" |

48" |

51 1/2" |

|

WA 60 |

60 1/2" |

60" |

63 1/2" |

|

WA 72 |

72 1/2" |

72" |

75 1/2" |

|

|

|

|

TYPICAL

INSTALLATION

|

|

|

1.

Install mounting plate using

the pre-drilled holes.

|

|

|

2.

Attach cabinet to mounting

plate using the two keyhole

slots. |

|

|

3.Install

optional micro-

switch(s) to door header. |

|

|

4.

Plug in unit using the 3-wire

cord/plug supplied. |

|

|

|

|

|

|

*

Junction Box only used with

optional microswitch(s). |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Properly

Installed Air Curtains Cut Cold Air Loss and Reduce

Humidity

|

|

|

|

|

|

|

APPLICATIONS:

Coolers * Freezers * Cold Storage * Air Conditioning

* Climate Control

|

|

|

|

|

|

The

purpose of the Air Curtains can reduce the rate of the

heat and moisture flow through an open refrigeration

door

60 to 80%. This is the finding of the first major impartial

survey. Research was made possible through the Refrigerated

Research Foundation and the University of Illinois. |

|

|

|

|

|

| Properly

installed Air Curtains can reduce the rate of the heat

and moisture flow through a cold storage building. These

doorways are subjected to wind pressure changes that

permit air to blow through the building. If this type

of installation is required, opposite doors should not

be opened at the same time. |

|

|

|

|

|

| Operation

of the Air Curtain is associated with three sources

of pressure that will retain the cold air by: |

|

1. |

Self-generated

pressure evolves from a non-circulatory type of Air

Curtain because the jet induces ambient

air into the stream. When the Air Curtain is installed

on the outside of a cold room, the air spills back into

the room and continues to do so until the pressure builds

up to such a point that the air stream deflects to

the outside. |

|

2. |

The

pressure form stack effect evolves when the cold air

in the room is denser than the warmer outside air.

The higher the ceiling, the higher the pressure becomes

inside the cold room. Therefore, the velocity of the

Air Curtain should be sufficiently high to compensate

for the outward pressure at the lower part of the cold

room. |

|

3. |

Wind

pressures occur because of the conversion of the velocity

pressure in the wind into static pressure.

Of particular significance is the stability of the Air

Curtain, which is directed by its outlet momentum. The

curtain of air must be able to withstand pressure variations

between the inside and the outside of the cold

room. The outlet momentum should be sufficiently sustained

and strong enough to stabilize the air at the

floor. Therefore, it is essential to incorporate in

the design of the Air Curtain, controls that increase

the

strength of the velocity to ensure a stiff curtain of

air and, decrease the velocity to prevent unnecessary

heat and moisture transfer at the door. |

|

|

|

|

|

| In

summary, the following observations are deemed more

significant for optimum efficiency: |

|

1. |

The

turbulence intensity should be as low as possible, but

sufficiently high to generate enough velocity to

barely reach the floor and divide as equally as possible. |

|

2. |

The

direction of the Air Curtain should be inclined slightly

toward the warm side for minimum heat transfer. |

|

|

|

|

|

|

|

|

|

NOTE: |

|

|

|

In

refrigeration, a high volume of air hitting

the floor is not necessary. We suggest the

airflow be adjusted so that it barely hits the

floor. Turbulent air at the floor level will

tend to form ice on the floor of freezers. |

|

|

|

Adjust

air louvers to obtain desired velocity. |

|

|

|

To

compensate for drafts, adjust

directional controls until airflow is

VERTICAL. The Air Curtain may be

mounted on either the warm or cold side

of the cooler with equal effectiveness. |

|

|

|

DO

NOT MOUNT THE AIR

CURTAIN IN THE FREEZER. |

|

|

|

When

using the Air Curtain to prevent

cold winter air from entering the building,

the units must be installed on the warm

side. |

|

|

|

|

|

Whispurr

Air, Air Curtain, Air Curtain Door, Air Curtain Heater,

Air Curtains, Air Doors, Door Air Curtains, Heat Curtains,

Mars Air Curtain, Mars Air Door, Warm Air Curtains,

and Insect Barrier from your source for material handling

equipment. |

|