|

|

|

|

|

|

• Type IA 300 lbs

duty rated each side

• Made of heavy-wall 6005-T5 aluminum

• Easy to maneuver and maintain

• 5 year warranty

• Adjustable in one foot increments

• Ideal for working over benches and

stadium seating |

|

|

|

|

|

Introducing

the world’s tallest A-frame ladder.

Where other ladders fall short, the Skyscraper from Little

Giant goes above and beyond. The Skyscraper is indeed

the world’s tallest a-frame ladder with a maximum height

of 21-feet, making ceiling-height work simple and safe.

The Skyscraper is perfect

for churches, auditoriums,

gymnasiums and other industrial applications. Plus it’s ideal

for working over benches and stadium seating. And because

it’s portable, the Skyscraper can be used in places where a

motorized lift or bulky scaffolding simply can’t go.

|

|

Safety

The Skyscraper is designed to be the safest ladder on the

planet. Since it’s adjustable, the Little Giant can be used

safely on stairs, ramps, curbs, docks or other uneven

surfaces. |

|

|

|

|

Little

Giant Skyscraper Features:

• Heavy-wall aircraft-grade

aluminum construction

• Rated to hold up to 300 lbs.

• Adjustable for use on stairs, curbs, docks and more

• Perfect for churches, gymnasiums or auditoriums

• Complies with all applicable OSHA ANSI A14.2

standards

• Includes a full 5-year Warranty |

|

|

Versatility

No other industrial, A-frame ladder gives you the versatility

of a Skyscraper One Skyscraper takes the place of

expensive motorized lifts, bulky scaffolding and flimsy

extension ladders. Plus it’s adjustable for safe use on

uneven surfaces. |

|

|

|

|

|

Little

Giant Skyscraper Configurations: |

|

|

|

|

A-Frame

Ladder

With a simple click of the patented hinge, the Little Giant

can be used as a traditional A-Frame ladder. |

|

|

|

|

|

|

|

|

Staircase

Ladder

Because it’s adjustable in one-foot increments, the Little

Giant allows one side of the ladder to be extended allowing

safe use on uneven surfaces like staircases, curbs or docks. |

Strength

The Skyscraper is made of heavy-wall, 6005-T5

aluminum—the very same material used in aerospace

construction. So it’s ultra-strong while remaining portable.

In fact, The Skyscraper is government-rated to hold up to

300 pounds, so it can handle virtually any industrial

application. |

|

|

|

|

|

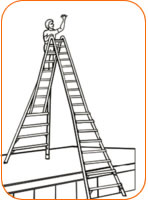

90°

Ladder

Traditional ladders make working close to walls nearly impossible. With

the Little Giant, one adjustment allows

you to safely work against any vertical surface. |

|

|

|

|

|

|

Accessories |

|

|

|

|

Work Platform

Model No. - 10104

300 lbs Rated |

|

Ladder Rack

Model No. - 15005

75 lbs Rate

Not available for #10121 |

|

|

|

|

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~ Add

items to your online shopping cart ~

Click a Part No. of the item you wish to

purchase. |

|

|

PRICES

FOR SKYSCRAPERS |

| Part No. |

Model

No. |

Stepladder

Height |

Storage

Height |

Weight |

Prices |

|

M15 |

8'-15' |

8' 7" |

60 lbs |

$988.30 |

|

M17 |

9'-17' |

9' 7" |

79 lbs |

$1,120.00 |

|

M21 |

11'-21' |

11' 7" |

103 lbs |

$1,368.30 |

|

|

PRICES

FOR ACCESSORIES |

Part

No. |

Description |

Weight

(lbs) |

Prices |

|

Work

Platform |

8 |

$53.33 |

|

Wall

Rack |

8 |

$33.33 |

|

Project

Tray |

- |

$46.67 |

|

Cargo

Hold |

- |

$25.00 |

|

Fuel

Tank |

- |

$40.00 |

|

|

|

Operating

Instructions for Little Giant Ladder System® |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| I.

Description - Skyscraper Telescoping A-Frame Ladder |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A.

Three basic components -The ladder is a telescoping A-frame unit comprised

of three basic components- an inner

ladder unit, which telescopes within two outer units. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1.

The inner ladder unit has a locking center hinge which allows the unit to

be used in the following configurations:

a. A-Frame (See Figure A-1)

b. Staircase (See Figure A-2) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2.

Locking mechanisms on the two outer units of the ladder permit the outer

telescoping sections of the ladder to be

adjusted in length. This lock assembly fits in any rung of the inner ladder,

allowing foot by foot adjustment on either

side of the ladder. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Figure A-1

A-Frame |

|

|

Figure A-2

Staircase |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| B.

The inner and outer side rails are made of aircraft grade aluminum. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1.

There are slip-resistant aluminum rungs on both inner and outer units.

2. Both inner and outer units are finished with slip-resistant feet. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Figure A-3

LOCKED |

|

Figure A-4

UNLOCKED |

|

Figure A-5

SIDE VIEW |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

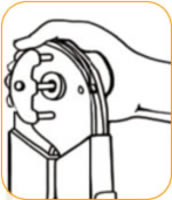

| II.

The Little Giant® Telescoping A-Frame Ladder has two mechanical component

parts: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

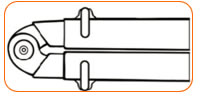

A.

The HINGE - located at the top of the ladder when it is in storage position,

permits you to alter the shape of the

ladder. The hinge locks in the following position. (See figures A-1, A-2) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1.

Unlock the hinge by pushing straight in on the palm button until it stays

in the open position on both hinges

(See figures A-3, A-4, and A-5). |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

a. NOTE- If there is pressure on the hinge lock pins it will make

it difficult to unlock the hinge. To relieve

pressure simply jiggle one half of the ladder back and forth until hinge

lock pins move without force. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

b. NOTE - DO NOT FORCE HINGE LOCK out with

any tools as it will cause permanent damage to the hinge

mechanism. It should never require more than light pressure to unlock the

hinge if the holes are properly aligned. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2. You

may now open the ladder to the A-frame position by pulling the two ladder

halves apart until both hinge

lock pins snap into the A-frame locked position. (See figure A-1) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3.

To restore the ladder to the storage position, disengage the hinge

locks in the

A-frame position and return the ladder to its storage position. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

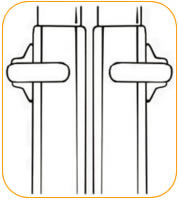

B.

The second mechanical component of the ladder is the LOCK ASSEMBLY.

There are four of these on each ladder. These permit you to change

the height of the

ladder (See figure B-1). |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| C.

Adjusting the height of the ladder for use in the A-frame position. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Figure B-1

Lock Assemblies |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1.

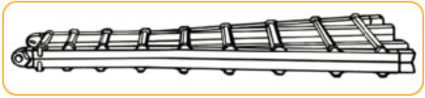

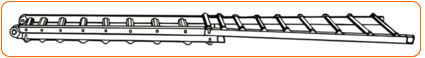

With the ladder in the closed, storage position; lay the ladder flat on

an unobstructed surface. (See figure C-1) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2.

Unlock both hinge locks. (See figures A-4 and A-5 on previous page) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3.

With the ladder down on the flat surface, (See figure C-1) pull the two

top lock assemblies out of the rung holes

of the inner ladder and rest them on the side of the outer ladder rail.

(See figures C-2 and C-3) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4.

Telescope top outer unit to desired length. (See figure C-4) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5.

Rotate ladder and place the extended outer unit on flat surface. (See figure

C-5) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Figure C-1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Figure C-2 |

|

Figure C-3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Figure C-4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Figure C-5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6.

Telescope remaining outer unit to desired length. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

7.

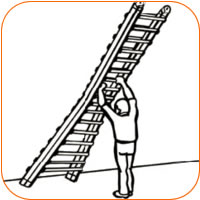

To raise the ladder, brace the feet against the wall and lift the hinged

top; walk (rung by rung) the ladder to a

vertical position. (See figures C-6 and C-7) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

8.

Open the ladder to the A-frame configuration by pulling the ladder halves

apart until the hinges lock into place. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Figure C-6 |

|

|

|

|

|

|

|

|

|

Figure C-7 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

9.

To return ladder to storage position: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

a.

In the A-frame position tip ladder to the side and lower to a flat surface. |

|

|

|

|

|

|

|

|

|

|

|

|

|

b.

Unlock both hinges and bring the ladder halves together. |

|

|

|

|

|

|

|

|

|

|

|

|

|

c.

Rotate ladder and place flat on surface. |

|

|

|

|

|

|

|

|

|

|

|

|

|

d.

Reverse procedures of steps C-1 through C-6. |

|

|

|

|

|

|

|

|

|

|

|

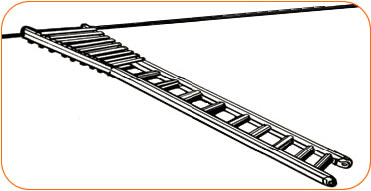

| D.

Adjusting the ladder in the staircase position. |

|

|

|

|

|

|

|

|

|

|

|

|

1.

Adjust ladder to desired height. (See steps C-1 through C-5) |

|

|

|

|

|

|

|

|

|

|

|

|

2.

Then adjust side desired for proper alignment to fit the staircase (See

figure D-1). |

|

Figure D-1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Little Giant Skyscrapers,

Aluminum Stepladders, Extension Ladder, Aluminum, Tallest A-Frame Ladder,

Adjustable for use on Stairs,

Curbs, Docks and more, OSHA, A-Frame Ladder, Staircase Ladder, and 90

Degree Ladder from your source for material handling

equipment. |

|